King Abdullah University Develops Red LED in InGaN

22-07-2020 | By Robin Mitchell

Researchers from King Abdullah University have developed a highly efficient red LED using Indium Gallium Nitride (InGaN). Why is the use of InGaN important, and how will it change future display technology?

Display Technologies

Display technologies have dramatically changed throughout the years with advancements, including size, weight, and overall resolution. The first displays utilised electron beams that would scan across a phosphorus screen, and these were known as Cathode Ray Tubes, or CRTs. This technology dominated the display market for 60 years, but the introduction of flatscreen technologies such as TFT made CRTs obsolete.

Current display technologies for user interface displays generally fall into one of the following categories.

-

TFT

-

LCD

-

LED

-

OLED

TFT and LCD

Thin-film transistor displays, or TFTs, are displays that utilise LCD technology for their pixels, but instead, use a thin film transistor on each colour element of each pixel. These displays provide better contrast and control when compared to LCDs, and are active displays. LCDs cannot address each pixel individually and are instead passive displays. While this causes a reduction in image quality and brightness, they consume less power than TFT displays.

LED and OLED

LED displays are those that utilise LEDs in each pixel. These displays offer high-quality images that are bright and can be used outdoors in sunlight. While some TVs are advertised as LED screens, the truth is that these TVs use LEDs as their backlight with an LCD overlay that controls the pixels, so an LED television is a type of LCD screen. LED screens are often found on large displays such as billboards, signs, and information posts. OLED displays are those that utilise organic elements which illuminate when stimulated by electrical current. When compared to LCD technologies, OLED screens are a magnitude of order better in terms of quality with greater brightness and better contrast with true black.

MicroLED - Small LED Lights

One technology that major display producers are trying to develop is the microLED display. These displays are essentially the same large LED displays used outdoors but shrunk in size for use with TVs and monitors. Such a screen requires incredibly small RGB LEDs that are currently very expensive to make. The reason for this is that red LEDs are traditionally made using AlInGaP (Aluminium-Indium-Gallium-Phosphide), while blue and green LEDs are made using InGaN (Indium-Gallium-Nitride). Therefore, a single microLED needs to be constructed by combining two different semiconductor devices onto the same package, which is a costly operation. If all three LEDs can be manufactured on the same chip, then the cost of the microLED would be significantly reduced, and thus would help to make microLEDs commercial.

Introducing the InGaN Red LED Structure

Recognising the needs by microLED technology, King Abdullah University have successfully created efficient red and amber LEDs using InGaN. But not only does the InGaN LED structure produce red light, which uses the same material as blue and green LEDs, it is also stable at higher temperatures which traditional red LEDs suffer from. By adjusting the size and temperature of the LED, the researchers were able to affect the output power of the LED as well as change the colour impression. The development of the InGaN red LED structure also led to the team developing a transparent electrical contact that utilises a thin-film of indium-tin-oxide.

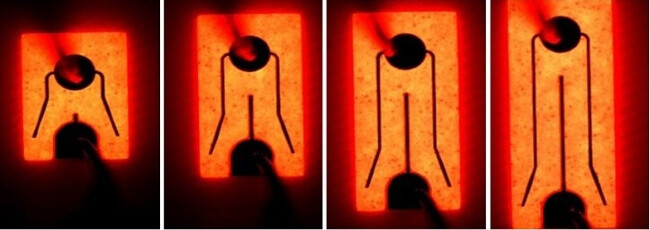

Optimizing the geometry, fabrication and electrical contacts is vital to maximizing the efficiency of the LED.

Credit: Zhuag et al.

The result is a bright energy-efficient LED that could pave the way for microLEDs of the future. “” A critical disadvantage of InGaP red LEDs is that they are not stable when operated at high temperatures. Therefore, we created InGaN red LEDs of different designs to realise very stable red-light InGaN sources at high temperatures. They have developed an InGaN red LED structure where the output power is more stable than that of InGaP red LEDs2. Also, its emission colour shift at high temperatures was less than half of that of those made with InGaP””

-

Zhuang, KAUST Core Labs

As the LED uses the same material as those used by green and blue LEDs, future microLEDs can utilise a single piece of semiconductor to make all three colours. This will significantly reduce the cost of microLEDs, and thus bring about microLED displays which will provide high contrast brilliant displays.

Read More