Researchers Develop Printed Paper Electronics that Generates Power

| 14-09-2020 | By Robin Mitchell

Researchers have demonstrated a system whereby nano pressure generators can be printed onto paper, and then interacted with over Bluetooth, which generates its own power. What is the triboelectric effect, what are the capabilities of the demonstration, and how can it be used practically?

What is the Triboelectric Effect?

While the term “triboelectric effect” may sound complicated and unusual, it is, in fact, one of the most fundamental effects that can be seen in electricity on an almost daily basis; static electricity. The triboelectric effect is the name given to the charging of dissimilar materials when rubbed together. For example, a rubber balloon if rubbed on hair or clothes will build up a static charge and can then stick to a wall.

What are Triboelectric Nanogenerators?

Triboelectric nanogenerators (TENGs), are nanoscale energy harvesters that can generate electricity when two dissimilar nanomaterials are rubbed against each other. The rubbing action is provided by mechanical energy, and thus triboelectric nanogenerators are mechanical to electrical energy converters. While the triboelectric has been observed for thousands of years, triboelectric nanogenerators had only been first demonstrated in 2012. When talking about TENGs, it’s crucial to understand how their energy capabilities are stated. Measuring the power produced by two nanoparticles would be rather pointless considering their nanoscale size, and the resulting energy produced. Instead, the power capability of TENGs is a measure of W/m2 as these materials can be scaled up in size. Thus, the first TENGs had power densities of 3.67mW/m2, but modern TENGs can now be designed for power outputs up to 313W/m2.

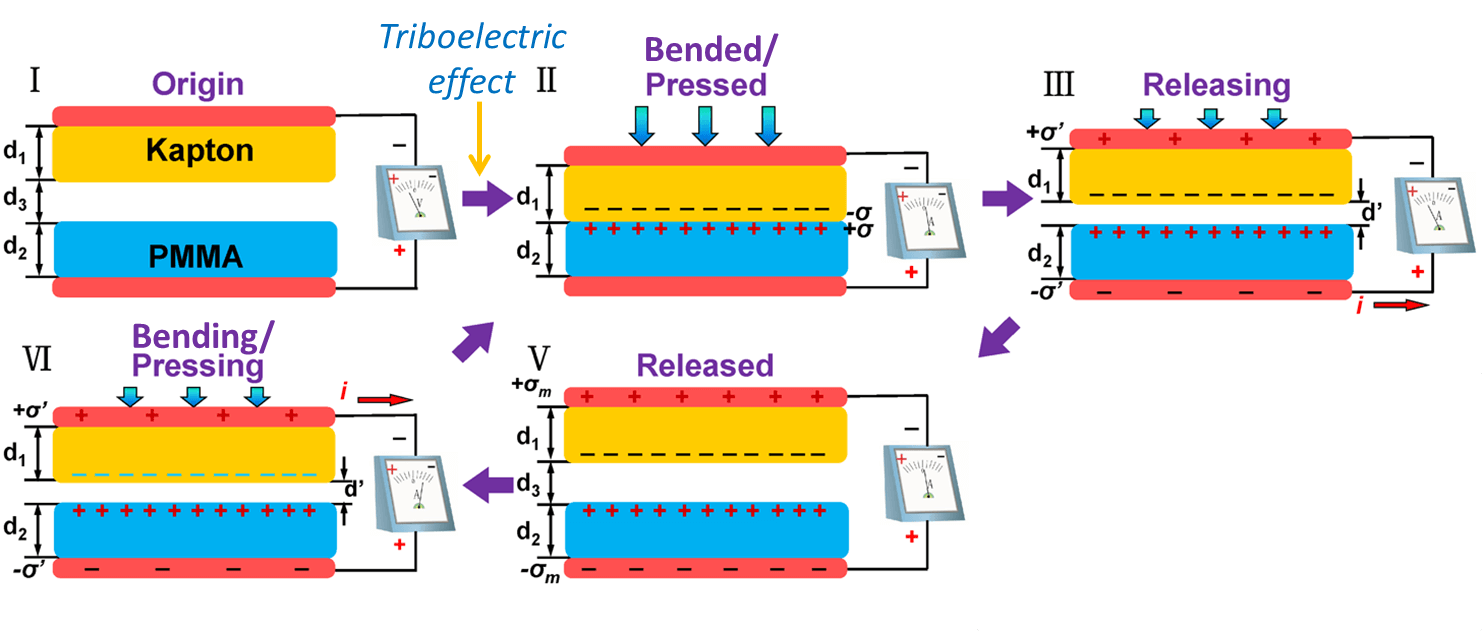

TENGs work when two nanolayers are placed on top of each other with a vertical separation between them. When a mechanical force is used to push the layers closer together, the triboelectric effect takes place, and charge transfer occurs within the structure. However, a potential difference is only noticed when separating the materials as an electric field forms between the two materials. If electrodes placed on each material are connected, then electric current results, which can be used to power circuitry.

By Wangsh05 - Own work, CC BY-SA 3.0, Researchers demonstrated printed nanotech.

Recognising the importance of TENGs, a team of researchers have demonstrated a printing process which can not only print TENGs pressure sensors but can be printed to common materials including paper and cardboard.

The first half of the research was the development of a coating that can repel liquid and dust. This coating can be applied to paper or cardboard to prevent damage from moisture, but it also allows for layers of material to be printed. This is where the second half of the research steps in; the printing of circuit layers directly to paper and cardboard. Using the specialised coating, researchers were able to print multiple circuit layers on-top of each other without them smudging or interfering with each other. The resulting layers allowed for the construction of vertical TENGs that both power circuitry and detect pressure on the paper. Since the other side of the paper is blank, a standard keypad interface can be printed, and thus a self-powered paper keypad can be created. This was demonstrated in a video showing the wireless capabilities of the paper keypad. The TENGs demonstrated can produce up to 300µW/cm2, and are rapidly fabricated by using spray deposition of essential compounds including organosilanes, conductive nanoparticles, and polytetrafluoroethylene.

However, one question remains over the demonstration; how was the paper interface able to transmit Bluetooth information? Watching the various videos, and the many reprinted articles online provide no answers. The pay-wall for the original article prevents access, and so one can only speculate how it was achieved. Transmitting Bluetooth information require packets and data encoding/decoding; thus, some level of complex circuitry is needed. In theory, a Bluetooth die could be integrated into the paper, and the use of bonding wires or contact pads allow for the die to read the button presses. Another method could be a simple printed RLC circuit that sends energy at a specific frequency that can be detected by Bluetooth receivers. Either way, the exact process to which this circuit transmits button presses is not discussed, and thus caution should be taken when understanding the capabilities of this research.

What potential applications exist for printable paper interfaces?

If the research really can power a Bluetooth device that is fully integrated into the paper keypad, then the applications for such a keypad are immense. The medical field could highly benefit from disposable interfaces for patients with highly infectious diseases, including COVID-19, Ebola, and the Bubonic Plague. The food industry could benefit from interactive interfaces for food packets that could allow customers to examine the contents as well as provide safety information. Courier industries could utilise such interfaces with buttons that users press to verify the package is there, and that it has been received.

Credit: Purdue University

A more novel use for such a technology would be custom projects and installations by both makers and specialists. For example, a custom project ordered by a client may require a set of unique controls, and the creation of a physical keypad with buttons is either too expensive or cumbersome. Makers may take advantage of the ability to craft custom keyboards that can be used to control a wide range of different projects such as home automation, remote-controlled systems, and computers.

Read More