Cortec Releases Fully Recyclable ESD Packaging Bag That Also Prevents Corrosion

Environment | 22-11-2022 | By Robin Mitchell

As engineers, we often worry about circuit design, PCB layout, and power performance, but we rarely give much thought to packaging and the effects of waste from our designs. What challenges does the packing industry face, what has Cortec announced, and how will packing considerations change in the future?

What challenges does packaging face?

The challenges and concerns faced by engineers have dramatically changed over the past few decades. At first, some of the most important concerns were profit margins and performance, but this has quickly been replaced with battery life, supply chain security, and environmental awareness. But while engineers go above and beyond to ensure that circuits use RoHS and REACH-compliant parts, the packaging that the final product will use rarely gets much attention; but this will soon change.

The increasing amount of global e-waste and plastic pollution is starting to see a change in attitude from the public, and this will undoubtedly see retaliation from customers who feel that companies are not doing their part regarding environmental safety. This is especially true for product packaging, which has received massive attention over the past years, with numerous supermarkets starting to explore new packaging options.

But while electronic products can easily be packaged in cardboard boxes and paper wadding, some electronics (such as bare PCBs) require ESD-safe packaging to prevent damage from unexpected static charges. At the same time, moisture can be a serious problem for components, whereby rust and corrosion affect the ability of a component to be soldered. This challenge is made worse when shipping goods using ships that are exposed to seawater.

Getting around these problems is easy to solve with ESD-safe foil bags that provide a faraday cage, while silicate bags provide moisture removal. However, these packages are rarely recyclable, can be expensive, and are difficult to work with as the need for silicate bags can require hand assembly.

Cortec announces new ESD-safe bags that are padded and fully recyclable

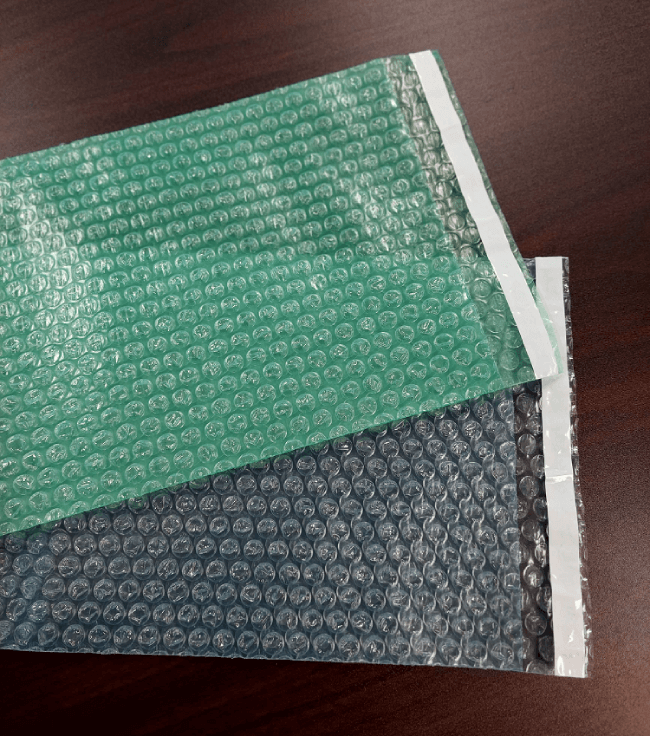

Recognising the challenges faced by packaging, Cortec recently announced the development of a new packaging option targeted at electronic products. The new bags, called EcoSonic, are ESD-safe which protects electronics from static charges, and also incorporate bubble wrap that protects electronics from impacts. Additionally, the new bags have a self-seal strip that removes the need for machinery, and the new bags are entirely recyclable, which helps to reduce the environmental impact of packaging.

But one feature that makes the new EcoSonic bags particularly interesting is the incorporation of Nano VpCl into the inside of the bag lining. This lining is a Vapor phase Corrosion Inhibitor which slowly releases corrosion-resistant compounds into the internal atmosphere, and these compounds eventually form a molecular-scale layer of film around the product inside the bag. This layer resists moisture which protects against corrosion while having no impact on solderability, which helps extend the components' shelf-life. The use of VpCl removes the need for additional desiccant bags and speeds up the process of product packaging. In addition to electronic components, the new bags can also be used for steel, aluminium, silver, copper, brass, plastics, optics, and elastomers.

How will packaging considerations change in the future?

It is clear that the public will start to move away from disposable packaging that is not recyclable, but it will also become important for manufacturers to choose recyclable materials while also making it clear how to recycle product packaging. This could be realised with the use of printed diagrams that show what bin each part of a package needs to go in or QR codes that take users to online instructions (possibly even video instructions).

While the packaging may be a boring subject to many, choosing the right type is essential for your product, the customer's perception of your product, and the well-being of the environment. As companies such as Cortec develop new packaging technologies, it would be a good idea as an engineer to be not only aware of the different packaging options available but how customers feel about specific packaging types and what it is they would like to see.