Hydrogel-Coated Heatsinks Enhance Passive CPU Cooling Efficiency

Insights | 07-02-2023 | By Jack Pollard

Researchers have uncovered a breakthrough in thermal management with their discovery of the impact a thin coating of hydrogel can have on the efficiency of heatsinks. By absorbing moisture and regulating temperature, this innovative material has the power to transform the way we manage heat removal and cooling in our devices. What challenges do heatsinks face, what did the researchers demonstrate, and could this be used in all applications?

What challenges do heatsinks face?

Just as circuit design, PCB routing, and component selection are critical in modern electronic design, so is thermal management. Almost all electronic components generate some amount of heat when used, and if this heat isn’t adequately dissipated, it can affect the operation of the circuit, whether it’s through degradation in performance or, worse, outright physical damage. In some cases, special PCB cut-outs have to be implemented around temperature-sensitive parts to minimise heat transfer through the PCB from other components.

Removing heat from components can be done in a number of different ways, but generally speaking, the most predominant method is the use of passive heatsinks. Simply put, a heatsink is a large thermal mass that conducts heat away from parts and dissipates this heat over a large surface area (usually with the use of fans). Natural air convection can then be used to extract heat from the heatsink, and if such airflow isn’t possible, then forced air from a fan can be utilised.

However, heatsinks suffer from a multitude of issues that can impact serious design limitations. Firstly, heatsinks are extremely heavy, and they have to be as they require mass to extract heat. The more power dissipated by a component, the larger the heatsink that is needed, and this can be particularly troublesome for portable devices.

Secondly, not all applications can use natural convection to remove heat, especially in compact designs. This means that assisted airflow via fans is required, but fans consume additional power as well as make a large amount of noise.

Thirdly, reducing the size of a heatsink can reduce the weight of a device, and only using passive cooling eliminates noise and additional power consumption, but this can only be done if the heat being generated is minimised. Therefore, devices must throttle processors, power circuity, and radio systems, all of which impact overall performance, and this is one of the leading reasons mobile devices struggle to integrate powerful processors.

Researchers demonstrate how hydrogel can increase heatsink performance

Recently, researchers published a new paper demonstrating how hydrogel can be used to improve the efficiency of typical heatsinks, and the technology behind the concept is available today. Simply put, the researchers applied a thin layer of hydrogel to the fins of a heatsink, which makes the surface of the heatsink porous to atmospheric moisture.

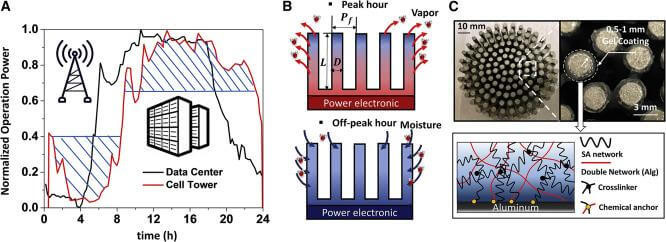

Under normal conditions, having any coating on a heatsink will impede its ability to dissipate heat as dissimilar materials create thermal barriers. As such, the application of hydrogel would seem to be counterintuitive. However, it turns out that hydrogel is hydrophilic, meaning that it readily absorbs moisture, and this means that a heatsink coated in hydrogel quickly absorbs atmospheric moisture when it’s cool. As the temperature of the heatsink increase, the trapped moisture evaporates, resulting in a massive cooling effect. This mode of operation is identical to how animals sweat to stay cool; the large amount of energy needed to evaporate water results in significant cooling.

Figure 1. Working principle of the moisture thermal battery (MTB) to mitigate on/off-peak temperature fluctuation of electronics

According to the researchers, their hydrogel hybrid was able to provide cooling of approximately 15˚C compared to a regular passive heatsink. Thus, a device that is power cycled can remain cooler during periods of high energy use and recharge the hydrogel during periods of low energy use. This effect is more notable in humid environments, such as those found in the tropics, where relative humidity can be between 80% to 90%.

Can this technology be used in all applications?

While this technology is ideal for applications that go through power cycles, it cannot be used for “always on” devices. As the moisture in the hydrogel will eventually be used up, the efficiency of the heatsink will drop considerably, meaning that devices will need to go through power cycles where the hydrogel can recharge its moisture content.

But there are plenty of applications that could take advantage of such heatsink technology. For example, data centres that undergo cyclic demands could utilise such heatsinks to reduce energy consumption costs, as well as cell towers that see little use during the evening.

It is unlikely that these heatsinks will make their way into everyday consumer devices, but the idea of electronic devices sweating to keep cool could yield some interesting designs. Maybe future devices will have water reserves that slowly keep heatsinks moist, or maybe future devices can be quickly cooled down by breathing on them.