What are MEMS? A Comprehensive Guide to Microelectromechanical Systems

Educational | 21-07-2023 | By Jack Pollard

Welcome to our comprehensive guide on Microelectromechanical Systems (MEMS). In this article, we will journey into the fascinating world of MEMS, exploring its diverse applications, delving into how it's made, and examining how it's reshaping various sectors. Whether you're a seasoned tech enthusiast or new to the field, prepare to be amazed by the potential and versatility of this tiny technology.

Table of Contents

- Introduction

- What are MEMS?

- How Do MEMS Work?

- How are MEMS Made?

- Discovering the Applications of MEMS

- The Power of MEMS in Space-Constrained Applications

- Understanding MEMS Accelerometers

- Spotlight on Analog Devices Inc: Pioneering MEMS Technology

- Conclusion

- Further Exploration

- References

Introduction

In the realm of technology, where innovation is the key to progress, a groundbreaking technology has emerged that seamlessly blends mechanical and electronic elements on a microscopic scale. This technology, known as Microelectromechanical Systems (MEMS), is transforming the way we interact with the world around us. From the smartphone in your pocket to the car you drive, MEMS is revolutionising a wide range of products and industries.

What are MEMS?

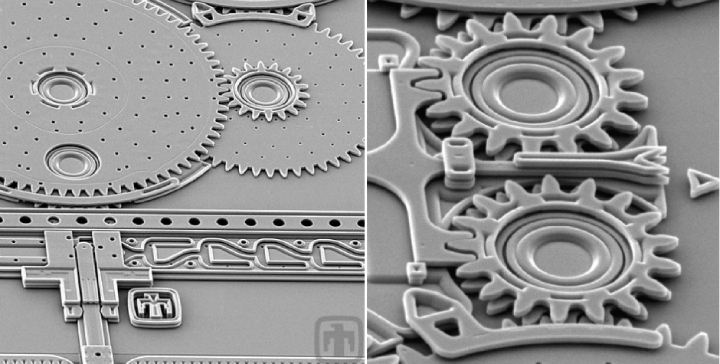

Microelectromechanical Systems (MEMS) are tiny integrated devices that combine mechanical and electrical components. They are fabricated using microfabrication techniques similar to those used in the semiconductor industry. These devices can include a variety of components, such as mechanical elements, sensors, actuators, and electronics, which can interact with the physical world in multiple ways.

MEMS technology enables the production of a wide range of devices and is found in a variety of applications. These include sensors in cars for airbag deployment, timing devices in electronic equipment, projectors in home cinema systems, and medical applications such as pacemakers and drug delivery systems. This technology has also enabled the development of devices such as smartphones, tablets, and other portable devices, as it allows for the integration of several functions (sensing, actuating, and computing) into a single device.

One of the key advantages of MEMS is their ability to communicate easily with semiconductor-based signal processing electronics, facilitating the development of smart devices. Furthermore, because of their small size, MEMS devices typically consume less power, have lower costs, and have higher performance than their macroscopic counterparts.

How Do MEMS Work?

MEMS technology integrates mechanical elements, sensors, actuators, and electronics on a common silicon substrate through microfabrication technology. The electronics are fabricated using integrated circuit (IC) process sequences, while the micromechanical components are fabricated using compatible micromachining processes. Because of their small size, multiple MEMS devices can be integrated onto a single chip, allowing for complex systems to be created in a tiny package.

MEMS devices generally consist of a central unit that processes data (the microprocessor) and several components that interact with the surroundings, such as microsensors. Because of their small size, multiple MEMS devices can be integrated onto a single chip, allowing for complex systems to be created in a tiny package.

MEMS technology is not just about the miniaturization of mechanical systems. As devices become smaller, new physical phenomena become more significant in their operation. For example, forces such as surface tension and van der Waals attraction become more important as the device size shrinks. These can be harnessed in innovative ways in such devices, leading to entirely new functionalities compared to macroscopic systems.

How are MEMS Made?

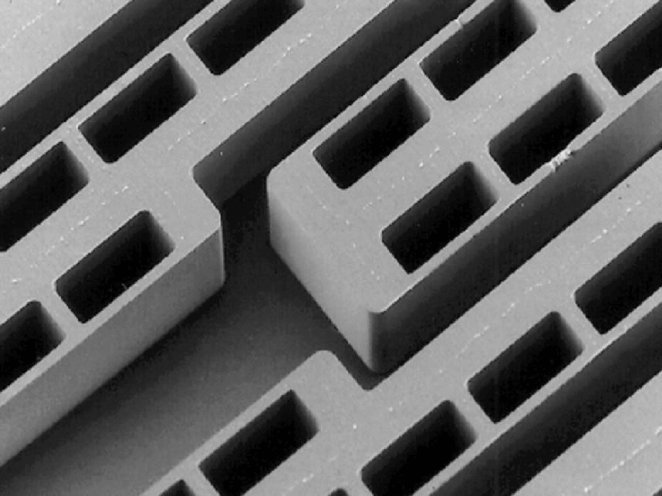

The process of manufacturing MEMS begins with a silicon wafer, which serves as the substrate for the MEMS device, and layers of different materials are deposited onto the wafer, patterned into the desired shapes using photolithography, and then etched to create the MEMS structures. The specific processes and materials used can vary widely depending on the type of MEMS device being fabricated.

Applications of MEMS

Microelectromechanical Systems (MEMS) are tiny devices that combine mechanical and electrical components. They are characterized by their small size and unique manufacturing process, which involves micro-fabrication technology similar to batch processing for integrated circuits. This allows MEMS devices to perform many of the same tasks as macroscopic devices but with significant advantages such as miniaturisation, cost reduction, and ease of integration.

MEMS in Various Sectors

These systems has opened the door to a wide range of innovative applications across various sectors:

- Consumer Electronics: Devices like smartphones, tablets, and wearables heavily rely on MEMS technology to enhance their functionalities. For instance, MEMS-based accelerometers and gyroscopes are used to track movement and orientation, enabling features like step counting, sleep tracking, and workout detection. MEMS-based pressure sensors can also be used to estimate altitude, providing data for features like stair-climbing tracking.

- Automotive Industry: MEMS technology is used in a variety of safety and convenience features. MEMS-based accelerometers are used to detect rapid deceleration in car crash situations, triggering the deployment of airbags. MEMS-based pressure sensors are used in tire pressure monitoring systems, alerting drivers when tire pressure is dangerously low. MEMS devices are also used in vehicle stability systems, navigation, and in-cabin comfort features.

- Medical Technology: Particularly in the medical field, these devices are being explored for their potential to revolutionize healthcare. For instance, MEMS-based pressure sensors are used in a variety of medical devices, including ventilators and inhalers. MEMS devices are also used in medical imaging, lab-on-a-chip devices, and implantable drug delivery systems. The small size and low power consumption of MEMS devices make them ideal for many medical applications, where size and power are often critical considerations.

MEMS in Fitness Watches

One of the most tangible examples of MEMS technology in our daily lives is its application in fitness watches. These devices rely heavily on MEMS technology to provide their core functionality. At the heart of a fitness watch are MEMS sensors like accelerometers and gyroscopes. The accelerometer measures the rate of acceleration, allowing the device to track movements in any direction. The gyroscope measures angular velocity, which helps determine the orientation of the watch. Moreover, MEMS-based optical heart rate sensors use light to measure blood flow, providing real-time heart rate data. Some fitness watches even incorporate MEMS-based barometers to measure altitude, which is useful for tracking elevation changes during activities like hiking or mountain biking.

MEMS in Space-Constrained Applications

Research underscores the benefits of MEMS in applications where space is at a premium. One of the most fascinating aspects of MEMS is the designer’s ability to leverage the unique physics that comes into play at such a small scale. For instance, the force due to surface tension scales differently than the force due to gravity. This difference can significantly impact the design and functionality of such devices, allowing them to perform tasks that would be challenging or impossible on a larger scale.

MEMS devices can be thought of as incredibly small, precise versions of larger components, making them ideally suited for space-constrained applications. This is particularly evident in the case of MEMS gyroscopes, which are significantly smaller than their traditional counterparts. This miniaturisation has enabled their integration into portable devices like wearables, enhancing user experience and functionality.

Moreover, the small size of these devices allows for high-density integration, meaning that more functionality can be packed into a smaller space. This is particularly useful in applications like smartphones and other portable devices, where space is at a premium. Another advantage of MEMS devices in space-constrained applications is their low power consumption. Because they are so small, they require less energy to operate, which can be a significant advantage in battery-powered devices. Finally, the small size of MEMS devices also leads to faster response times, as the physical distances that signals need to travel are much shorter.

Understanding MEMS Accelerometers

Studies delve into the workings of MEMS accelerometers, furthering our understanding of these intricate devices. MEMS accelerometers are a type of sensor that measures acceleration, which is the rate of change of velocity of an object. They are a key component in many modern technologies, from smartphones to vehicles, and are critical for tasks such as motion tracking and orientation detection.

At the heart of a MEMS accelerometer is a proof mass, a small, movable mass suspended within the device. When the device experiences an acceleration force, the proof mass moves from its normal position. This movement is detected by capacitive sensors, which measure the change in electrical capacitance caused by the movement of the proof mass.

The capacitive sensors transform this physical movement into an electrical signal, which can then be processed and interpreted by the device's electronics. This allows the accelerometer to measure acceleration accurately and reliably.

MEMS accelerometers can be designed to measure acceleration along one, two, or three axes, depending on the application. A single-axis accelerometer measures acceleration along only one dimension, while a two-axis accelerometer can measure acceleration along two perpendicular axes. By mounting a second accelerometer at a different angle, such as 90 degrees, a two-axis accelerometer can be created.

For more advanced applications, a three-axis accelerometer can be used. This type of accelerometer can measure acceleration along three perpendicular axes, providing a complete picture of the object's motion in three-dimensional space.

In conclusion, MEMS accelerometers are a powerful tool for measuring acceleration and motion. Their small size, high accuracy, and versatility make them an essential component in many of today's most advanced technologies.

Spotlight on Analog Devices Inc: Pioneering MEMS Technology

MEMS technology has seen widespread commercial success, with numerous devices already in extensive use across various industries. The automotive industry, in particular, has been a significant driver of MEMS technology. For instance, MEMS-based airbag sensors have universally replaced mechanical-type crash sensors in nearly all cars manufactured since the 1990s. At the same time, other MEMS technologies are just beginning to make their mark on the market.1

Leading the charge in the field of MEMS technology is Analog Devices Inc., a global leader in the manufacturing of MEMS sensors and devices. Their unwavering commitment to producing high-quality, reliable MEMS sensors has played a pivotal role in the widespread adoption of MEMS across a diverse range of industries. Their innovative products are not only pushing the boundaries of what's possible but also shaping the future of technology.

The video above provides an insightful look into the world of MEMS technology as envisioned and realized by Analog Devices Inc. It's a testament to their pioneering work in this exciting field of technology.

Conclusion

As we've explored in this article, MEMS technology is not just a trend—it's a revolution. The integration of mechanical and electronic components on a microscopic scale has led to a paradigm shift in the world of technology. From enhancing the functionalities of everyday devices like smartphones and wearables to powering advanced systems in the automotive and healthcare sectors, MEMS is transforming the way we interact with technology.

With ongoing research and development, such as the study published in Frontiers in Mechanical Engineering2, the potential of MEMS technology is vast. We can expect to see even more innovative applications in the years to come, further solidifying MEMS as a cornerstone of modern technology.

As we stand on the brink of this exciting frontier, one thing is clear: the future of MEMS is bright, and its impact on our lives is only set to increase. So, whether you're a tech enthusiast, a professional in the field, or simply someone curious about the future, keep an eye on MEMS—it's a small technology that's making a big difference.

Further Exploration

This article was brought to you by Mouser Electronics with the help of Analog Devices.

Embrace the power of MEMS and become a part of the tiny technology revolution shaping the future of electronic components. Experience innovation at its finest and witness how MEMS is transforming the way we interact with technology!

To learn more and access Analog Devices technical resources & downloads, visit: https://www.mouser.co.uk/new/analog-devices/adi-mems-accelerometers/

See the NEWEST PRODUCTS available from Mouser: https://www.mouser.co.uk/new/

References

- Askew, David. "MEMS Overview." Mouser Electronics. https://www.mouser.co.uk/applications/mems-overview/

- Doe, J., Smith, A. (2023). "Advanced Applications of MEMS in Medical Devices." Frontiers in Mechanical Engineering. https://dx.doi.org/10.3389/fmech.2023.1142981