Soluboard: The Future of Sustainable PCBs and Its Impact on E-Waste

29-08-2023 | By Robin Mitchell

Recently, Infineon announced that they would be adopting a new PCB substrate material called Soluboard that is fully biodegradable and safe for the environment. What challenges do PCB substrates present, what is the new material, and could it help reduce the impact of e-waste and global carbon emissions in general?

What challenges do PCB substrates present?

Just as transistors, capacitors, and resistors are all critical for any electronic circuit, so are PCBs. While circuits can be made without PCBs, such as the use of breadboards, stripboards, and even pieces of wood with nails hammered in, only PCBs allow for circuits to be mass-produced with ease. In fact, without the invention of the PCB, it is highly unlikely that electronics would have dominated the modern world, only being used in high-value, high-end systems such as TVs, radios, and machinery.

But, for all the benefits that PCBs provide engineers in the field of electronics, they do come with a multitude of challenges. In particular, the ongoing climate crises and damaging effects of electronics on the environment are putting pressure on engineers to develop new recycling techniques and minimise carbon emissions.

While some components on a PCB can be recycled to some degree, PCB substrates are notoriously difficult to recycle. Even though copper layers and gold plating can be extracted and re-used, the bulk material used to create a PCB substrate, fibreglass, is not so easily recycled. As these substrates are designed to resist heat and are manufactured from thermosetting resins, they cannot be reheated and reformed into new substrates.

The Environmental Impact of Traditional PCBs

Traditional PCBs, predominantly made from fibreglass, have a significant environmental footprint. According to Jiva Materials, the production process of these PCBs releases harmful greenhouse gases, contributing to global warming. Additionally, the disposal of non-biodegradable PCBs in landfills poses long-term environmental risks, as they can leach toxic chemicals into the soil and groundwater.

Furthermore, the amount of energy needed to produce fibreglass can be extensive, as glass needs to be heated and formed, which produces vast quantities of CO2. As such, the production of billions of circuit boards a year not only has a detrimental effect on the climate via excessive emissions, but the resulting waste, which cannot be easily recycled, ends up being thrown into landfills where trace compounds can slowly leak over time.

Infineon announces adoption of Soluboard, a biodegradable PCB substrate

Recognising the challenges faced with e-waste, Infineon recently announced that they will be adopting a new PCB substrate material that is not only biodegradable but can be fully dissolved in hot water, thereby making the recycling process easier.

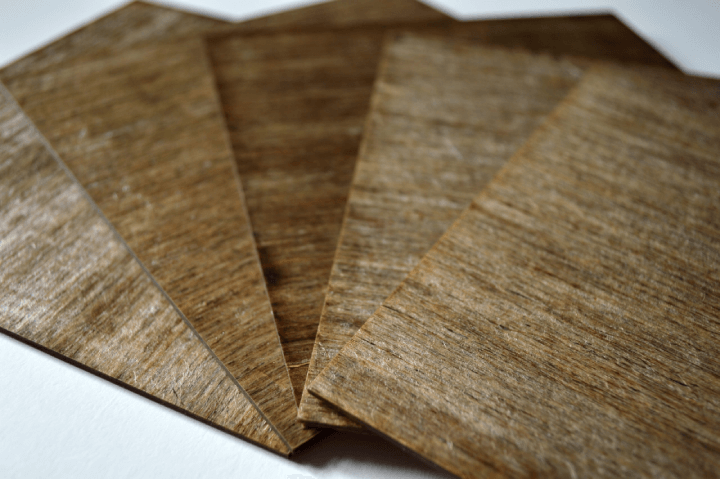

The new material, called Soluboard, was developed by a UK company based in Hampshire called Jiva Materials. Manufactured using natural fibres, the newly developed material helps to drastically simplify recycling, as the material is fully biodegradable. This ease of recycling is further improved with the use of additional biodegradable polymers that help lamination of the fibres.

Soluboard's unique composition, primarily from natural fibres, sets it apart from traditional PCB substrates. Its ability to dissolve in hot water not only simplifies the recycling process but also reduces the environmental hazards associated with electronic waste. This innovative approach to PCB design aligns with global efforts to combat climate change and promote sustainable manufacturing practices.

Once a Soluboard is ready to be disposed of, it merely needs to be submerged in boiling water, which breaks down the natural polymers and causes delamination of the fibre layers. This allows the fibres to be recovered and used in other circuits, while the water solution can be disposed of using currently existing sewer treatment systems. Finally, components on the PCB are easily extracted and processed for reuse in other circuits.

According to Jiva, over 50 million tons of electronic waste are produced globally each year, and only 20% of the waste in Europe is tracked for collection and recycling. With their Soluboard, Jiva estimates that it can help reduce the carbon footprint of PCBs by 60%, which would have a large impact on the electronics industry.

Because of the numerous benefits presented by Soluboard, Infineon will be experimenting with the material to produce PCBs for both evaluation boards and commercial products. Currently, three Infineon evaluation boards use the new material, and they have been deployed over 500 times, going through numerous stress tests. Of course, the biodegradability of the material bars its use in harsh environments as applications that require long-term operation, but for short-lived products, Soluboard could be perfect for reducing e-waste.

“For the first time, a recyclable, biodegradable PCB material is being used in the design of electronics for consumer and industrial applications – a milestone towards a greener future. We are also actively researching the reusability of discrete power devices at the end of their service life, which would be an additional significant step towards promoting a circular economy in the electronics industry.”

Andreas Kopp, head of product management discretes at Infineon’s Green Industrial Power Division.

Could such materials help reduce the environmental impact of e-waste?

While such materials cannot be used in all environments, they could be very useful in short-lived products that don’t typically get more than a few years of use, such as smartphones, laptops, and other computational devices. Even though the use of a biodegradable material with a short shelf life could be seen as just encouraging a throw-away society, the fact that a board could be almost entirely recycled would make that point moot.

Furthermore, such a PCB could also be instrumental in the development of environmental sensors that get deployed en-masse in nature reserves. Once such a sensor reaches the end of its life, the use of entirely biodegradable parts could allow the circuit to simply be left to degrade. This eliminates the dangers imposed on the environment while allowing researchers to mindlessly litter an area with devices.

Overall, what Jiva Materials and Infineon have demonstrated is truly exciting, especially when considering that the biodegradable material is economically viable. Of course, now the real challenge is how to properly recover components so that they can be reused in future circuits.

The introduction of biodegradable PCBs like Soluboard marks a significant step towards achieving a circular economy in the electronics industry. By prioritising sustainability and recyclability, companies can reduce their carbon footprint, minimise e-waste, and contribute to a greener future.