KERI's Metamaterials Drive New Efficient, Stretchable TEGs

27-11-2023 | By Robin Mitchell

Recently, researchers have managed to create a new thermoelectric generator with a high degree of flexibility thanks to the use of new metamaterials. What challenges do thermoelectric generators face in the field of wearables, what did the researchers demonstrate, and are such devices practical?

Dr. Hyekyoung Choi (left) and Dr. Min Ju Yun (right) from KERI demonstrating the stretchable and flexible thermoelectric generators developed using metamaterials.

Dr. Hyekyoung Choi (left) and Dr. Min Ju Yun (right) from KERI demonstrating the stretchable and flexible thermoelectric generators developed using metamaterials.

What challenges do thermoelectric generators face in the field of wearables?

Despite the many advances in technology, wearable electronics are still a niche market that struggles with a number of challenges. One such challenge is the dependency on ridged electronic components, which cannot bend and flex organically with skin, meaning that practical wearable devices are often cumbersome and ridged in nature. While flexible electronic components are being developed, they are nowhere near as practical or as commercial as traditional components.

The second challenge that wearables face is power. Again, just like how flexible electronic components are in their infancy, power sources capable of being comfortably worn and flex with the human body are virtually non-existent. Energy sources that have a degree of flexibility are either still being developed or lack the energy density needed to power even the simplest of circuits.

But instead of trying to create flexible batteries for powering future wearables, some researchers are exploring the use of wearable thermoelectric generators (TEG). Unlike batteries, a TEG is able to indefinitely produce power so long as there is a sufficient temperature gradient between the wearer and the surrounding air.

Now, it is clear that the first problem which would arise from such a power source is that various climates around the world would see vastly different performance capabilities of any worn TEG. For example, a TEG optimised to work in UK weather where the outside temperature never exceeds body temperature would fail to operate in desert climates without being flipped around.

But more importantly, for all the benefits that wearable TEGs may present, it is hard to find materials that can support flexible designs. Most TEGs currently in development are based on ceramic materials which, when stretched and compressed, elongate in perpendicular planes (a good example of this is how squeezing rubber results in an increase in its length).

As such, trying to create delicate TEG structures with good thermal properties that can be manipulated without damage presents monumental difficulties.

Researchers create flexible TEG via metamaterials

Recognising the challenges faced with wearable electronics and TEGs, a team of researchers from the Energy Conversion Materials Research Center in Korea have recently published their findings on a new TEG utilising metamaterials that do not exist in nature.

The material in question, a gasket used to support the TEG, has a metastructure that, when compressed or stretched, sees each side of the material change in the same way. Such a material is said to have a negative Poisson’s ratio and can be ideal for ensuring that flexible electronics maintain their shape and structure when stretched and compressed.

Innovative Design Enhancing TEG Efficiency

A groundbreaking aspect of the recent TEG advancements is the introduction of a partially air-filled deformable gasket. This gasket, supporting the thermoelectric legs, is pivotal in reducing heat loss and improving heat transfer from the skin. This design innovation leads to a 30% larger temperature gradient compared to conventional TEGs, significantly boosting energy conversion efficiency. Such an increase in efficiency could be a game-changer in the practical application of wearable TEGs.

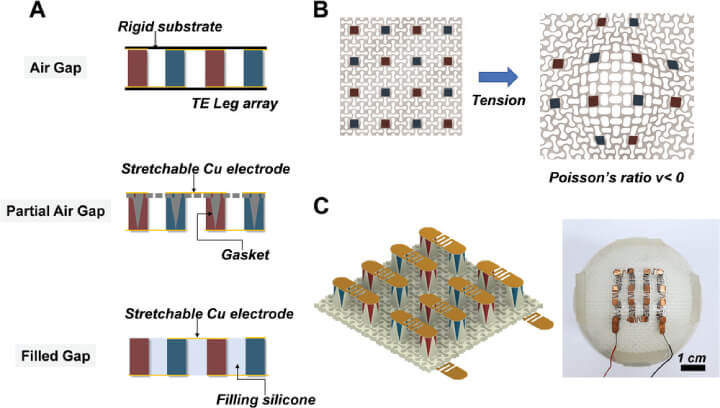

Exploring the Innovative Design of Stretchable Thermoelectric Generators: This figure presents the design and fabrication of stretchable thermoelectric generators (TEGs) with an auxetic deformable gasket. A) It contrasts a conventional rigid TEG, a flexible silicon-filled TEG, and the novel deformable gasket-based TEG, highlighting the partial air gaps in the design. B) It shows both undeformed and deformed states of the auxetic structured gasket, which exhibits a negative Poisson's ratio. C) The left side illustrates a schematic of the TEGs, while the right side displays a photograph of the actual fabricated TEG module, featuring 8 pairs of thermoelectric legs attached to a curved surface with a 40 mm radius.

Exploring the Innovative Design of Stretchable Thermoelectric Generators: This figure presents the design and fabrication of stretchable thermoelectric generators (TEGs) with an auxetic deformable gasket. A) It contrasts a conventional rigid TEG, a flexible silicon-filled TEG, and the novel deformable gasket-based TEG, highlighting the partial air gaps in the design. B) It shows both undeformed and deformed states of the auxetic structured gasket, which exhibits a negative Poisson's ratio. C) The left side illustrates a schematic of the TEGs, while the right side displays a photograph of the actual fabricated TEG module, featuring 8 pairs of thermoelectric legs attached to a curved surface with a 40 mm radius.

Auxetic Metastructure: A Leap in Wearable Technology

The auxetic metastructure of the gasket, characterised by a negative Poisson's ratio, is a key feature in these new TEGs. This unique property allows the material to expand and contract uniformly, making it highly adaptable to the contours of human skin. This adaptability not only enhances comfort but also ensures consistent performance, a critical factor in wearable technology.

Creating the gasket involved the combination of silicone with air gaps, but while these air gaps helped with producing a negative Poisson ratio, it also helped to provide thermal insulation for the integrated TEGs. According to the researchers, the finished TEG device was 35% more stretchable than all previous attempts in the field of TEGs and was able to provide as much as 20 times the energy density compared to previous attempts.

Testing of the device has yielded energy densities of around 2 to 3 µW/cm2, which is by no means enough to power everyday devices but a significant upgrade compared to previous attempts. Furthermore, these numbers were achieved in ambient temperatures of 23˚C, enabling these devices to work in most commercial and residential environments, even in hot climates. Finally, the researchers demonstrated the wearable TEG on a human arm, being able to power a small LED.

Are such devices practical?

While the work done by the researchers is truly ingenious (and will undoubtedly lead to new discoveries and developments), wearable TEGs powering electronic devices are unlikely ever to materialise. Unless processor technology can be made hyper-efficient to the point that smart devices consume less than a watt of power, the tiny power output from TEGs will never be enough.

That isn’t to say that such TEGs won’t find an application in the future; they could very well be ideal for energy harvesting of small IoT devices, deployed en-masse in remote areas, or used for devices that only need to be powered once in a blue moon. But to say that TEGs could one-day power wearable devices is more of a dream than a practical goal that can be achieved, certainly not in our lifetime.