Turning E-Waste to Gold: The Surprising Role of Cheese Byproducts

Insights | 28-03-2024 | By Robin Mitchell

Cheese byproduct converts electronic waste into gold.

Key Things to Know:

- The global e-waste problem is escalating, with millions of metric tonnes generated annually, necessitating innovative recycling solutions.

- Researchers have developed a groundbreaking method using cheese byproduct whey protein to efficiently extract gold from electronic waste.

- This new technique not only promises to reduce environmental harm but also to improve the economic viability of e-waste recycling.

- The process represents a significant step towards sustainable e-waste management, potentially transforming the recycling industry.

As the e-waste problem continues to grow, rising costs of raw minerals, the increasing scarcity of crucial elements, and the escalating damage faced by the environment are putting pressure on world governments, engineers, and the public alike. Recognising the challenges faced by e-waste, researchers have recently demonstrated a potential new technique that uses old cheese waste to extract gold from electronics more efficiently. What challenges does e-waste recycling introduce, what did the researchers demonstrate, and could such a process help tackle the challenges of e-waste for the next generation?

What challenges does e-waste recycling introduce?

The role that electronics play in everyday life cannot be understated; it practically underpins everything we do, from paying bills to finding sources of entertainment. But while electronics continue to play an increasingly important role in civilisation, it introduces a whole range of challenges that need to be addressed.

One such challenge is the extreme rate of change found in the electronics industry, which can quickly leave many behind. Those who are able to keep up with the latest tech trends can take full advantage of new hardware and software offerings, while those who are unable to do so are often left behind.

Another challenge is the numerous security and privacy issues faced with adding electronics to everyday devices. The inclusion of microphones, cameras, and sensor arrays into products, along with internet connectivity, make them all a potential spying device as well as a platform to launch attacks.

The environmental impact of e-waste is profound, with less than 20% being properly recycled. This not only leads to significant loss of precious metals and other resources but also contributes to severe environmental degradation and health risks due to the release of toxic substances into ecosystems.

The Growing Crisis of E-Waste Accumulation

However, one universal issue that continues to worsen with each passing year remains above all else: e-waste. Simply put, all electronic devices eventually break down, become outdated, or simply unwanted, and have to be discarded. Considering that most electronic device users are consumers, much of this e-waste finds itself in the bin, which itself is rarely recycled.

"You can’t get much more sustainable than that!" - Professor Raffaele Mezzenga, regarding the use of a cheese byproduct to recover gold from electronic waste.

Understanding the magnitude of the e-waste problem is crucial. According to the Global E-waste Monitor, the world generated a staggering 53.6 million metric tonnes of e-waste in 2019 alone, a figure that is expected to grow exponentially. This highlights the urgent need for innovative recycling methods that not only mitigate environmental harm but also recover valuable resources efficiently.

Because of the high amount of e-waste not being recycled, landfills can quickly become contaminated with numerous chemicals and compounds including lead, mercury, and arsenic, all of which can pollute the local environment. Furthermore, if this waste finds its way into an incinerator, then the resulting compounds are ejected into the air, which further pollutes the atmosphere.

The Silver Lining: Valuable Metals in E-Waste

One saving grace of modern electronics is that they contain a lot of precious metals, including gold, silver, and copper. Considering that these elements are becoming increasingly more expensive each year, the economic returns on recycling e-waste also increase.

However, extracting these valuable minerals from e-waste is easier said than done, and the use of extremely caustic chemicals (including nitric acid, sulphuric acid, and hydrochloric acid) makes the recycling process dangerous beyond reason. Making matters worse, the energy needed to melt down and extract the precious metals also introduces challenges with regard to CO2 emissions.

The innovative approach by ETH Zürich researchers, leveraging whey protein from cheese byproducts, represents a significant leap towards sustainable e-waste recycling. This method not only reduces the reliance on hazardous chemicals but also showcases the potential for circular economy practices by repurposing food industry waste for environmental benefits.

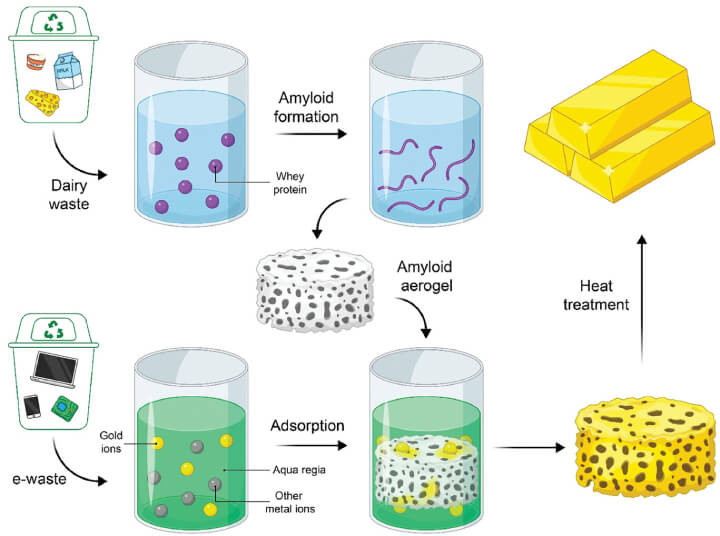

Figure 1 dives into the heart of turning waste into gold, quite literally. Here, we see how researchers cleverly use whey, a byproduct of cheese, alongside e-waste to extract pure gold. It's a brilliant showcase of circular economy at work, turning what we'd normally discard into valuable resources. This schematic gives us a peek into the future of recycling, where every bit of waste finds a second life.

Recycling e-waste also requires a high degree of manual labour, as devices need to be properly organised and stripped down. For example, e-products need to have their casing, wires, and batteries removed before bare PCBs can be thrown into large chemical vats.

This use of manual labour increases the cost of recycling while exposing workers to potentially dangerous levels of toxic compounds. Furthermore, as large amounts of e-waste find their way into developing nations, safety precautions are rarely followed, resulting in large-scale harm.

Researchers use old cheese waste to extract gold

It is clear that the recycling process for e-waste is complex and expensive, but considering that the rewards include substantial amounts of gold, silver, and copper, such a venture can be profitable. If this process could be made more environmentally friendly, then e-waste recycling would effectively become a no-brainer. Recognising the benefits of e-waste recycling, researchers from EHT Zurich have published their findings on a newly developed method for extracting gold from e-waste, which has been claimed to significantly reduce energy consumption while increasing the final profit margin substantially.

Highlighting the significance of this research, the method's ability to selectively absorb gold from electronic waste without the need for additional chemical processes is a game-changer. It exemplifies how interdisciplinary research can lead to breakthroughs that address both environmental sustainability and resource recovery.

Innovative Approach to Gold Recovery from E-Waste

To achieve efficient gold extraction, the researchers turned to cheese waste that contains whey proteins. By using Amyloid formation, the researchers turned the whey protein into an aerogel structure which consists of a delicate whey protein structure with large voids. If the formation of the aerogel is carefully controlled, it becomes possible to create a meta-structure with selective absorption properties, meaning that its structure determines what elements it bonds well to.

Scrap e-waste is then sorted into its circuit boards and submerged in an Aqua regia solution, which dissolves most metals, including gold. At this point, numerous filtration cycles would be needed to further separate the gold from the solution, which itself is difficult and energy intensive (while also requiring reducing agents).

However, if the whey protein aerogel structure is placed into the solution, gold particles form flakes on the structure. This use of a meta-structure allows for gold extraction without needing to use further chemical processes, and once the aerogel structure has fully absorbed the gold particles, it can be melted down to form a raw gold nugget.

The resulting nugget is able to have a purity of around 90 - 91%, which is extremely high considering that the process is still in its infancy and has plenty of room for growth and refinement.

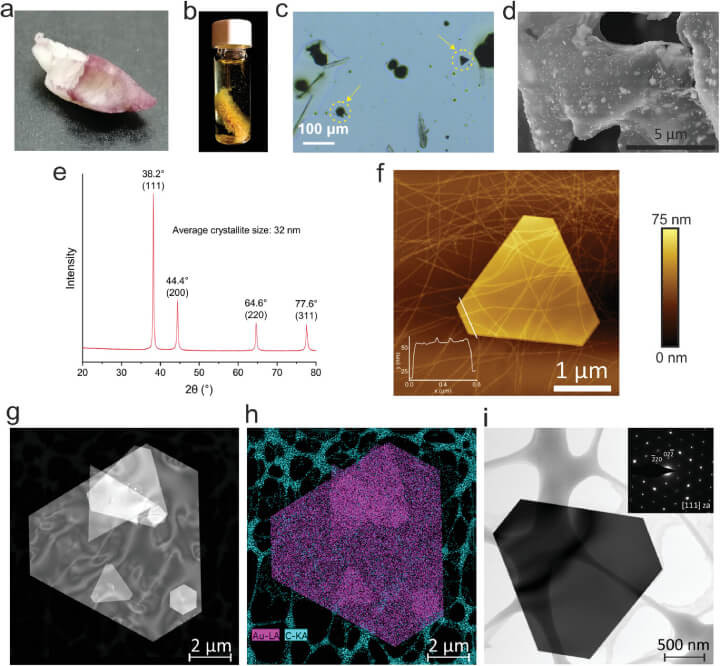

Figure 3 unveils the microscopic marvels of gold recovery through the lens of advanced materials science. Here, we explore the transformative journey of gold ions, as they converge into nanoparticles and crystalline formations, all facilitated by the pioneering use of AF aerogels. This visual narrative not only captures the essence of cutting-edge research but also symbolizes a leap towards sustainable e-waste recycling practices, marrying the realms of technology and environmental stewardship.

Gold nanoparticles and crystal formation through AF aerogels. a) The emergence of gold nanoparticles on the AF aerogel's surface following the absorption of a 10 ppm gold metal blend. b) The generation of gold crystals on AF aerogel within a 4 mL glass vial filled with a 1000 ppm metal mixture. c) Optical microscopy snapshots of the AF aerogel specimen depicted in (b). d) SEM imagery showcasing an AF aerogel adorned with freshly formed gold crystals. e) XRD analysis revealing the structure of gold nanoplates synthesized via the adsorption and subsequent reduction of Au3+ on AF aerogel. f) AFM imagery of gold hexagonal microplates created by AF (with an inset detailing the height profile across the microplate). g) The HAADF–STEM visualisation. h) A color-coded EDS spectrum image of the particle shown in (g), illustrating the Au-Lα and C-Kα signal overlay. i) A BF STEM micrograph of an Au-platelet alongside its SAD pattern obtained in electron diffraction mode, showcasing the [111] plane orientation of the platelet.

This breakthrough has the potential to transform the e-waste recycling industry by making the extraction of precious metals not only more environmentally friendly but also more cost-effective. As the technology matures and scales up, it could significantly lower the barriers to recycling e-waste, encouraging more widespread adoption of recycling practices globally.

Could such processes help with tackling e-waste?

Regardless of the difficulties faced by recycling e-waste, it has to be done simply because allowing e-waste to build up in landfills is not acceptable. Trying to reuse old hardware isn’t always a solution, meaning that, at some point, circuits need to be broken down into their raw materials and given a new lease of life.

But if this process can be made economical, not only will it help fund research to find new ways to reuse old electronics, but it will also encourage users to recycle their old electronics. In fact, if e-waste recycling can be made highly profitable, it may see users exchange e-waste for cash in buyback schemes.

What the researchers have demonstrated is that not only can valuable metals be extracted from e-waste more efficiently, but can be done using waste from other processes. If the process described by the researchers can be further refined, it will very likely lead to a new era of e-waste management, paving the way to a future where e-waste is no longer seen as a hindrance, but as a source of economic growth.

Moreover, the application of such innovative recycling techniques could pave the way for new regulatory frameworks and incentives. Governments and industries could be inspired to collaborate more closely on e-waste management solutions, integrating circular economy principles into the core of electronics design and disposal.

References