IIoT Basics and Key Benefits of Industrial Internet of Things

Insights | 08-08-2024 | By Gary Elinoff

The Industrial Internet of Things. Image source: SAP

Key Takeaways about An Introduction to Industrial Internet

- The Industrial Internet of Things (IIoT) is a key component of Industry 4.0

- The IIoT can decrease costs and improve reliability across a broad range of applications

- The IIoT depends on a broad range of smart sensors

Introduction

The term “Industrial Internet” was first invented by General Electric Corporation in 2012. As described by GE[1], the Industrial Internet of Things [IIoT], “It is the network of a multitude of industrial devices connected by communications technologies that results in systems that can monitor, collect, exchange, analyze, and deliver valuable new insights like never before. These insights can then help drive smarter, faster business decision-making for industrial companies.”

The IIoT is one of the key factors in defining and making possible what is now widely known as Industry 4.0, which is described by IBM[2] as being “synonymous with smart manufacturing, is the realization of the digital transformation of the field, delivering real-time decision making, enhanced productivity, flexibility and agility to revolutionize the way companies manufacture, improve and distribute their products.”

The smart factories that are made possible by the IIoT feature smart sensors that translate physical data such as temperature, pressure and distance into electronic notation that can be transmitted over electronic networks such as the classical internet, WiFi or even the new, low latency 5G cellular networks. The results include vast improvements in automation and especially in predictive maintenance.

As we’ll see, the benefits and potentials made possible by the IIoT and its superset, the Internet of Things (IoT), extend far beyond smart factories alone.

Some of the Key Benefits of IIoT

There are many applications of IIoT that will be discussed in this and subsequent Electropages articles. For starters, let’s examine a few examples cited by Splunk, a CISCO Company[3]:

- Predictive maintenance. Classically, factories employed crews of employees to periodically inspect the works. If anything was amiss between inspection, the problem continued until a breakdown occurs. IIoT systems employ smart sensors (more about them later) to monitor individual machines for important physical indicators such as temperature and vibration. The results are digitized and streamed up via the cloud, where they can be analyzed remotely through predictive analytics algorithms to determine if and when the equipment is likely to fail.

- Industrial Automation. With smart sensor monitoring critical machine parameters continuously, not only is each machine studied individually, but their performance can be analyzed communally. How well are they playing together as a team? The data are streamed to centrally based analytical engines that can determine weak spots, synergies and other vital insights. The end result will be factories that produce better products more quickly and more cheaply.

- Robotics. Robots are used to perform tasks that are hazardous for humans or simply too boring. But since one of the other major virtues of robots is to reduce labor costs, why go to expense of employing human “foremen”, when robotic operational data can be streamed over the cloud, and analyzed with other factory considerations.

- Logistics. The advantages here are endless. IIoT can automatically provide actual inventory levels and determine the status of perishables. Freight handlers can track shipments in real time and collect data to improve shipping efficiency.

Applications of the IIoT. Image source: Splunk

IIoT Smart Sensors

Smart Sensors need to measure relevant physical parameters, digitize them and pass them onto the gateway. They are often used with legacy machines, as newer devices most often have the smart sensor built in. In either case, the diagram below illustrates the operation of a smart sensor.

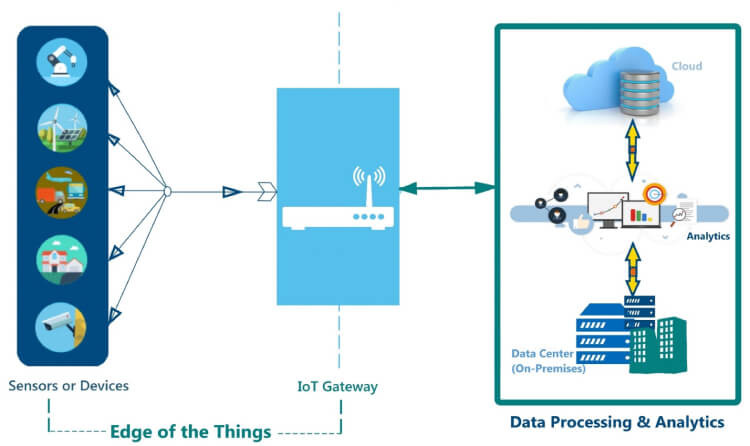

Applications of the IIoT. Image source: SolisPLC

While smart sensors may have built-in facilities to communicate, the sensors in this diagram connect to an IoT gateway. And it’s no coincidence that the diagram says “IoT gateway” because, as we’ll see, there is really no true demarcation between the IoT and the IIoT. The gateway launches the sensor(s) electronic data stream onto the internet. At the far end, the internet delivers the information to the data center, which can be located anywhere. Analytical processing takes place, and signals can be sent back down to the “Edge of Things”, where the course of action mandated at the data center such as perhaps, opening or closing a valve, can be put into effect.

IIoT Connectivity

IIoT can be said to effect changes at “the edge”, or, at the point where the electronic control system meets the devices that the IIoT is meant to monitor and/or control. This is not usually the place where the data processing takes place.

That data processing might be done in the same building, in which case simple WiFi may provide the link. If near-instantaneous control is needed, low latency 5G can be employed. And the internet, the same internet over which you are reading this report, can connect the “Edge of Things” to analytical engines anywhere in the world.

The Edge

One of the hallmarks of the IIoT is Artificial Intelligence (AI). Through AI, IIoT systems can gather information and make decisions about courses of action, and it can do its thing without reference to human actors, and respond to situations at unprecedented speed.

The question is – where are the AI engines located? The answer is either continents away at a remote server, or right at the spot, where “the rubber meets the road”, at the “edge” where the IIoT system physically meets the system that it is monitoring and controlling. Both methods have their advantages. We describe edge based AI in a previous Electropages article.

With server-based AI, an IIoT node must rely on an AI server thousands of miles away and then wait for the decision to come back, and precious time is lost. If the IIoT system is part of a weapons system, that delay may be unacceptable, and the communication is additionally subject to enemy hacking.

In any case, the popularity of server-based AI is subjecting the internet itself to unprecedented demand, and delays are cropping up. The recent advent of cheap AI chips and IP means that edge-based AI, although less comprehensive than AI located on a server, is now a very practical solution in many cases, even in situations where security, although always an issue, is not the manifest concern.

IoT vs IIoT

There really is no clear boundary, and the largest differentiation may be the need for reliability.

The IoT is generally used for consumer concerns, like the interface between a smartwatch and a cellphone. If there is a malfunction, an amateur runner may not learn how many miles they ran in a workout or their average heart rate – annoying but of no real significance.

On the other hand, the failure of an IIoT system governing the interjection of a strategic missile may well have disastrous ramifications. That’s why reliability is an absolute must for IIoT systems.

Challenges and Opportunities

The challenge in the West and in Japan is that the demand for goods and services is ever increasing, while at the same time the working age population is fast decreasing. The IIoT will make it possible to reconcile these two seemingly contradictory realities.

A new type of “factory worker” will be needed. No longer will a strong man with a hammer and wrench be the factory floor “foot soldier.” The new hero will be a person of either sex with technician level competency in digital electronics. Fortunately, our smartphone obsessed members of Gen Z are better suited to this role than they realize.

The IIoT depends heavily on the internet, but as pointed out in a previous Electropages Article, the internet is barely keeping up with present demands. Considerable effort and investment will be required to keep up with these ever-increasing demands.

Protecting IIoT applications from malevolent outsiders is a constant challenge. An enemy nation state doesn’t need to bomb a factory to shut it down, it just needs to hack into its data flow. This issue is the single greatest challenge to the IIoT, and will be dealt with in subsequent Electropage articles.

Wrapping Up

Industry 4.0 is also known as the 4th and latest phase of the Industrial Revolution. As defined by McKinsey[4], “Steam propelled the original Industrial Revolution; electricity powered the second; preliminary automation and machinery engineered the third; and cyberphysical systems—or intelligent computers—are shaping the Fourth Industrial Revolution.”

The Industrial Internet of Things is the driving force behind the Fourth Industrial Revolution. The public is most aware of the impact of this newest edition of the industrial revolution on the factory floor, but its impact goes far beyond that, into warehousing, logistics, healthcare, agriculture, the exploitation of space and into weapons of war.

Two of the key drivers of the IIoT itself are smart sensors and connectivity.

Smart sensors measure physical realities such as pressure, vibration, and temperature, rendering them into digital representations. Their analog, electromechanical actuators, convert digital commands into actions.

With Edge Computing, the smart sensor’s readings are analyzed by local decision engines, which directly command the actuators. Alternatively, the controlling decisions are made on servers located anywhere in the world that can connect to the internet.

AI is increasingly a part of the decision making process, and the availability of inexpensive AI chips is making Edge Computing more and more practical and attractive.

References:

1. What is the Industrial Internet of Things (IIoT)?: https://www.ge.com/digital/blog/what-industrial-internet-things-iiot

2. What is Industry 4.0?: https://www.ibm.com/topics/industry-4-0#:~:text=IBM-,What%20is%20Industry%204.0%3F,improve%20and%20distribute%20their%20products

3. The Industrial Internet of Things: A Primer: https://www.splunk.com/en_us/blog/learn/industrial-internet-of-things-iiot.html#:~:text=An%20IIoT%20platform%20is%20a,that%20connect%20the%20two%20together.

4. What are Industry 4.0, the Fourth Industrial Revolution, and 4IR?: https://www.mckinsey.com/featured-insights/mckinsey-explainers/what-are-industry-4-0-the-fourth-industrial-revolution-and-4ir

Glossary of Key Terms

- Edge Computing. Where computational decisions are made directly adjacent to where the data inputs are gathered, without access to remote decision engines.

- Latency. The amount of time that it takes to contact a remote decision engine, plus the time it takes for the remote system to decide on a course of action, added to the time it takes for the decision to travel back to the location of the original source of the inquiry.