Choosing the Right Contract Electronics Manufacturer (CEM)

Insights | 04-09-2024 | By Jack Pollard

As a prominent UK-based, privately-owned Contract Electronics Manufacturer (CEM), Tioga has rapidly grown into one of the leading names in the industry. With their headquarters in Derby, they offer a comprehensive suite of cutting-edge services that span state-of-the-art electronic assembly, complete product manufacturing, and full turnkey solutions. This breadth of service allows Tioga to cater to various industry needs, from prototype development to full-scale production.

What sets Tioga apart is its commitment to stringent quality standards, as evidenced by their key certifications. They hold the AS/EN9100 accreditation, which is the gold standard for quality management in the aviation, space, and defence sectors, and the ISO 13485 certification, which guarantees adherence to the rigorous requirements of medical device manufacturing. These certifications are a testament to their dedication to delivering top-tier quality and reliability across highly regulated industries.

Tioga's approach is firmly rooted in fostering long-term relationships with their clients. By offering flexible and high-quality manufacturing solutions that are customised to meet specific client requirements, Tioga positions itself as more than just a service provider — they become an integral partner in their clients' success.

Clarify Your Requirements

Before beginning your search for a Contract Electronics Manufacturer (CEM), it's essential to have a clear understanding of your project's specific needs. Defining these requirements upfront will not only streamline the selection process but also ensure that the chosen CEM aligns with your goals.

Start by considering what type of support you require from the manufacturer. Are you looking for design assistance to refine your product concept? Do you need help with prototyping to create early-stage models for testing? Or are you ready to move straight into full-scale production?

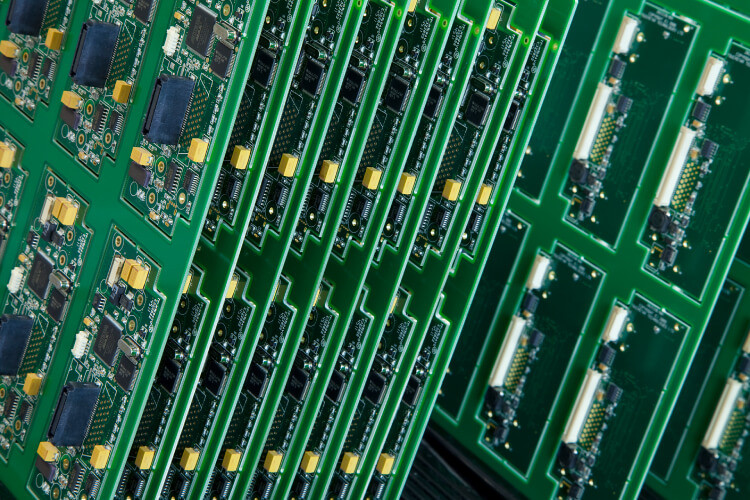

Additionally, it's crucial to pinpoint the focus of your manufacturing needs. For some, it may involve precise PCB assembly, where the focus is on creating circuit boards with surface mount or through-hole technology. Others may require complete product manufacturing, where the CEM handles everything from component assembly to final packaging. Being clear about these factors will guide your search and help ensure you find a partner that meets your technical and operational needs.

Check Essential Accreditations

When selecting a Contract Electronics Manufacturer (CEM), ensuring they hold the right industry-specific certifications is crucial, particularly for sectors like aerospace, defence, and medical devices. These industries demand the highest levels of precision and quality, which is why certifications like AS/EN9100 and ISO 13485 are essential.

The AS/EN9100 certification is a global standard specifically tailored for organisations working in the aviation, space, and defence sectors. It ensures the CEM meets stringent quality management requirements, including risk management, product safety, and on-time delivery.

For the medical industry, ISO 13485 is the benchmark. This certification focuses on the unique regulatory requirements for medical devices, emphasising risk management, traceability, and stringent quality control processes. Manufacturers holding this certification demonstrate their ability to consistently meet both customer and regulatory demands in the medical field.

These accreditations serve as a mark of quality and reliability, guaranteeing that your chosen CEM adheres to the highest industry standards and regulatory frameworks.

Always Visit Potential CEMs

Conducting a site visit is a critical step when evaluating potential Contract Electronics Manufacturers (CEMs). A firsthand look at their operations provides invaluable insight into their capabilities, allowing you to better assess whether they are the right fit for your needs.

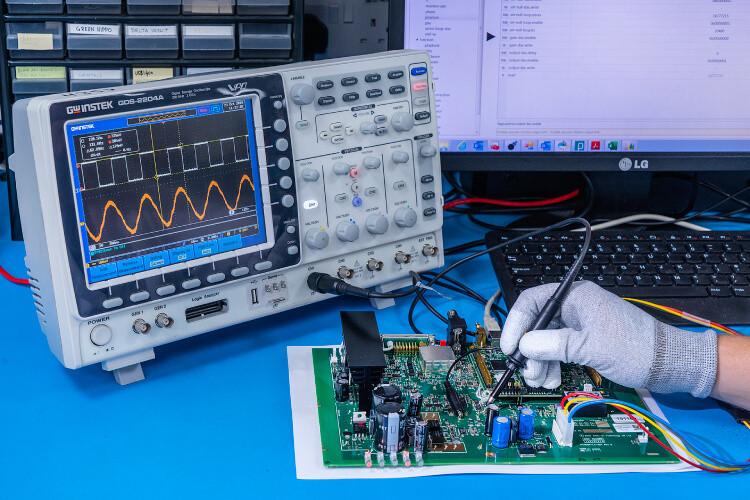

By visiting the site, you can observe the CEM's manufacturing capabilities in action. This allows you to verify that their equipment, processes, and overall production setup align with the scale and complexity of your project. It's an opportunity to assess whether they can meet your technical requirements and quality standards.

Additionally, a site visit offers a chance to gauge the team dynamics and workplace culture of the CEM. A cohesive and experienced team is essential for ensuring smooth collaboration and high-quality outcomes. Understanding how the team functions can help you evaluate whether they can seamlessly integrate with your own processes.

Finally, seeing the facility in person helps ensure that the CEM's operational practices align with your company's values and expectations. From quality control to safety protocols, a site visit ensures that the CEM operates in a way that reflects your standards, fostering a better long-term partnership.

Evaluate the True Cost

When evaluating the cost of a Contract Electronics Manufacturer (CEM), it's important to look beyond just the price on the quote. While cost is a significant factor, making it the sole focus can lead to overlooked issues that may affect your project's success.

Consider whether the quote includes high-quality standards and value-added services. For example, does the manufacturer offer guarantees on quality control? Are their processes ISO certified, ensuring that they meet industry benchmarks? These aspects are critical to ensuring that the CEM can deliver consistently high-quality products.

It's also important to evaluate the availability of additional services like Design for Manufacturability (DFM) and engineering support. DFM ensures that your product is designed in a way that streamlines manufacturing, reducing production costs and the likelihood of errors down the line. Meanwhile, having access to expert engineering advice can be invaluable when troubleshooting design or production challenges, further optimising your project.

Finally, flexible manufacturing options play a key role in long-term success. A CEM that can scale production up or down as needed and adapt to design changes or unforeseen issues is more likely to support your project's evolving needs. Opting for a manufacturer that balances cost with flexibility and comprehensive services can offer better value in the long run.

Prioritise Long-Term Partnerships

Building a successful relationship with a Contract Electronics Manufacturer (CEM) goes beyond the basic transactional nature of business. A long-term partnership can provide numerous benefits, ensuring that your project not only meets current requirements but also evolves efficiently over time.

At Tioga, this philosophy is central to their approach. They work as an extension of their client's team, embedding themselves into the process to fully understand the client's specific needs. This close collaboration ensures that the solutions provided are tailored, flexible, and aligned with the client's strategic goals.

Tioga places a strong emphasis on understanding and addressing specific client requirements, which allows them to deliver customised solutions. Whether it's design refinement, prototyping, or full-scale production, Tioga's team prioritises delivering high-quality, reliable service that meets the unique demands of each project.

Furthermore, Tioga is committed to fostering long-term collaborations by consistently delivering exceptional service. This focus on maintaining enduring partnerships ensures that clients receive continuous support, flexibility, and innovation, positioning them for ongoing success with a reliable manufacturing partner by their side.

Conclusion

In conclusion, selecting the right Contract Electronics Manufacturer (CEM) is a decision that can significantly impact the success of your project. It's essential to carefully consider several key factors throughout the process.

Start by clarifying your project's specific needs, whether it's design assistance, prototyping, or full-scale production. Ensure the CEM holds relevant industry certifications, such as AS/EN9100 or ISO 13485, to guarantee adherence to quality and regulatory standards. Site visits are also invaluable for assessing the CEM's capabilities and ensuring their operational practices align with your values.

While cost is important, it should be balanced with the value-added services offered, such as engineering support and flexible manufacturing options. Finally, prioritise a CEM that views the relationship as a long-term partnership—one that acts as an extension of your team, fully understanding your needs and committing to your project's success over the long haul.

Finding a partner that fits both your organisational and technical requirements will provide a strong foundation for future success. Long-term collaborations with the right CEM will yield not just reliable manufacturing but also strategic growth for your business.

To find out more about how Tioga could help you, visit: https://bit.ly/3XjXAjM