MLCCs with New Soft Termination Variant Ensure Automotive Electronics Pass Rigorous Dew Tests

Technical Analysis | 21-10-2024 | By Jack Pollard

By Benjamin Blume, Samsung Electro-Mechanics Co.

The automotive sector is renowned for its stringent testing standards. Only the most robust electronic components can endure the severe environmental conditions of these evaluations. One such test, the automotive dew test, specifically examines the reliability of systems that incorporate multi-layer ceramic capacitors (MLCCs) with silver-epoxy soft terminations. For engineers striving to pass these challenging tests, adopting a more advanced MLCC solution is crucial. Samsung Electro-Mechanics Co. (SEMCO) presents an optimized solution with its latest soft termination variant.

The Role of Soft Terminations in Automotive MLCCs

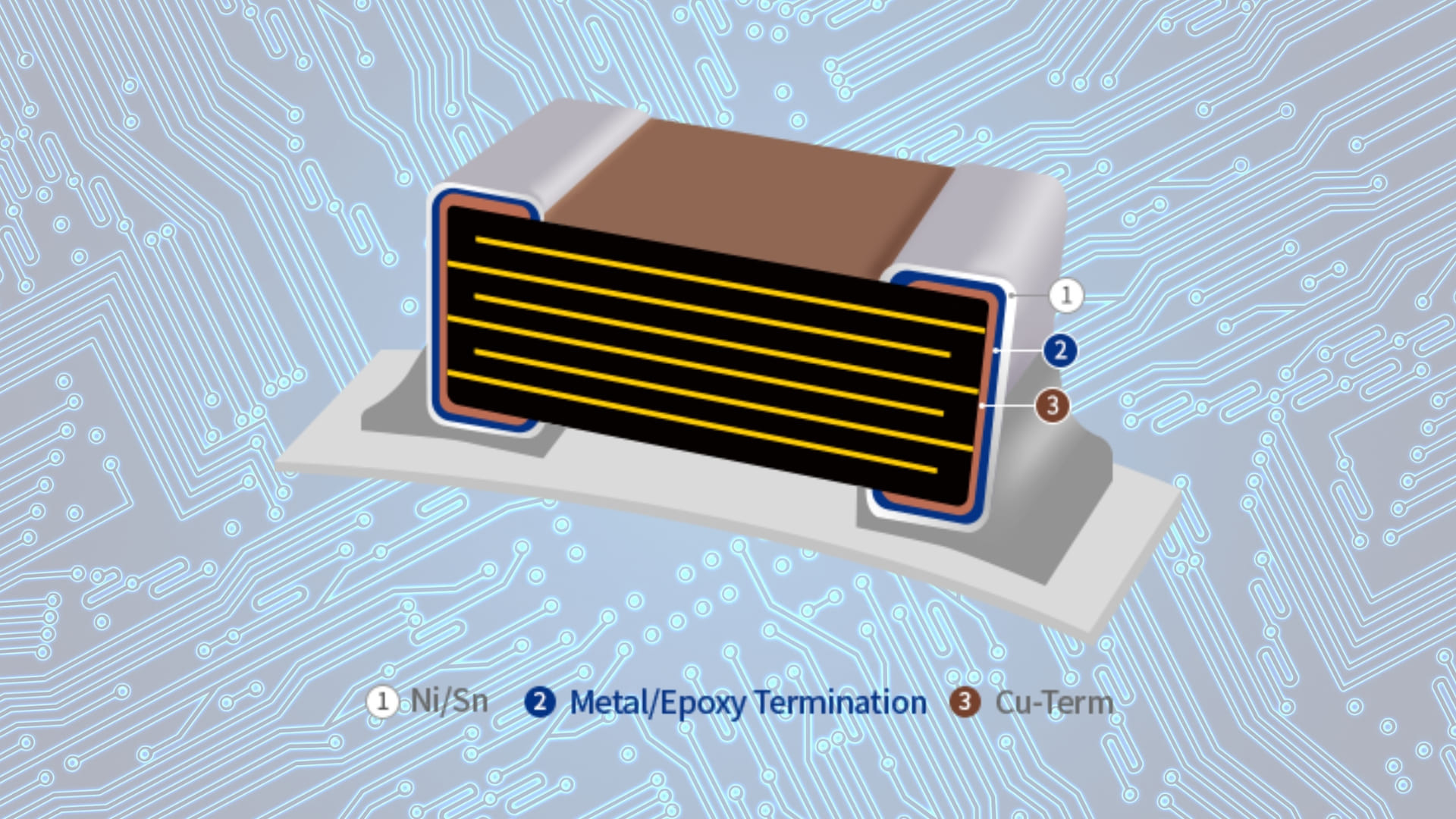

In automotive electronics, Class II MLCCs are especially prone to mechanical stress due to the brittle nature of their ceramic materials. Soft terminations are designed to absorb some of this mechanical strain, reducing the likelihood of cracks and short circuits, particularly when the circuit board bends. Silver-epoxy has traditionally been used for soft terminations, but silver presents problems in high-humidity environments, such as those simulated in the automotive dew test, due to its high migration rate. SEMCO’s new variant, based on copper-epoxy, overcomes these challenges, offering a robust solution for passing the automotive dew test.

Powertrain and Electronics Systems Under Stress

High humidity presents significant risks in various automotive applications, including powertrain systeams like inverters, battery management, and DC-DC converters. MLCCs used in these systems, particularly DC-Link MLCCs, must endure the automotive dew test's stringent conditions. Systems such as transmission control units (TCUs), electronic control units (ECUs), and on-board chargers are also vulnerable to dew-induced failures if proper MLCCs are not employed.

The primary concern lies with MLCCs that carry a constant DC load and experience minimal AC load, making them more susceptible to silver migration under humid conditions. This risk escalates in high-voltage applications where greater migration force is present, compromising the reliability of the system.

Beyond powertrain applications, other critical automotive systems like airbag control units (ACU), electric power steering (EPS), and HVAC systems are also at risk of moisture-related issues. Advanced driver assistance systems (ADAS), including components like smart cruise control (SCC), LiDAR, and autonomous control units, rely heavily on MLCCs that need to pass rigorous dew testing.

SEMCO’s Copper-Epoxy Innovation

SEMCO’s solution to the silver migration problem lies in its adoption of copper-epoxy for soft terminations, a material the company has used for over a decade. Unlike silver, copper is far less susceptible to migration in humid environments, ensuring reliability even under the most demanding dew test conditions. SEMCO continues to expand its line-up of high-capacitance, high-voltage, and larger case-size MLCCs, all featuring this innovative termination material.

Since 2023, all new automotive MLCCs from SEMCO feature this copper-epoxy technology, making them the only supplier offering this material in a high bending-strength MLCC line-up. Other manufacturers may offer coated MLCCs to protect against migration, but these solutions often come with a higher cost. SEMCO’s approach provides a more cost-effective, high-performance alternative.

Bending Strength and Crack Prevention

Another key feature of SEMCO’s new MLCC variant is its superior bending strength, which helps prevent cracks in critical areas, such as near connectors or mounting holes. One of the most common failure modes for MLCCs is cracking, which can occur during PCB separation, assembly, or when screws are inserted too close to the MLCC. These cracks may not cause immediate failure but can lead to moisture ingress over time, reducing insulation resistance and ultimately causing a dielectric breakdown or short circuit.

SEMCO’s soft termination variant offers up to 5mm of bending strength, a significant improvement over other solutions in the market. This enhanced robustness helps ensure that the MLCCs can withstand the mechanical stresses of automotive environments, reducing the likelihood of failure and associated warranty costs.

Conclusion: A Solution for Today’s Automotive Needs

SEMCO’s new soft termination MLCC variant represents a significant advancement in automotive electronics. By solving the long-standing issues of silver migration and providing exceptional bending strength, SEMCO offers automotive manufacturers a reliable, cost-effective solution for meeting the stringent demands of modern automotive testing, such as the dew test. With over a decade of success, SEMCO continues to lead the way in MLCC technology, delivering high-reliability components that stand up to the most challenging conditions.