Flexible RISC-V Microprocessor Under $1 Redefines Electronics

Insights | 04-11-2024 | By Robin Mitchell

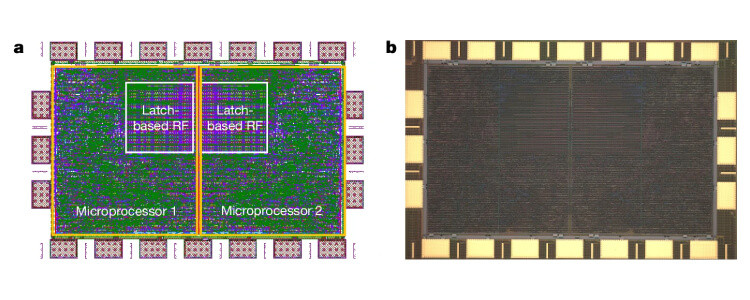

a, Diagram showing the layout of the 9 mm × 6 mm test chip, which includes two Flex-RV microprocessors. b, Microscope image of the test chip die.

In a groundbreaking development, Pragmatic Semiconductor and collaborators have engineered a flexible, ultralow-power microprocessor, the Flex-RV, based on IGZO technology and the open-source RISC-V architecture. This innovative chip, capable of running machine learning tasks, opens doors for affordable wearable healthcare devices, smart labels, and more. With the potential to transform soft electronics, the Flex-RV's flexibility and cost-effectiveness mark a significant leap in democratising computing.

Key Things to Know:

- Breakthrough in Flexible Electronics: The Flex-RV microprocessor, developed by Pragmatic Semiconductor, is a flexible, ultralow-power chip based on IGZO technology and RISC-V architecture, capable of running machine learning tasks efficiently.

- Cost-Effective and Environmentally Friendly: By utilising IGZO thin-film transistors, the Flex-RV reduces production costs and environmental impact, making it suitable for cost-sensitive applications like smart packaging and wearable healthcare devices.

- Revolutionising Healthcare and AI: The chip's flexibility and reprogrammability allow for integration into wearable tech and AI systems, expanding possibilities for patient monitoring and seamless interaction with everyday objects.

- Durable Performance Under Stress: The Flex-RV has been tested to maintain performance even when bent to a radius as small as 3 mm, showcasing its robustness for use in dynamic environments and industrial applications.

How does the Flex-RV's IGZO-based design enable flexibility without the need for special packaging, what advantages does the open-source RISC-V architecture offer in customising processors and avoiding licensing fees, and what impact could the programmable machine learning hardware accelerator have on AI applications in flexible electronics?

The Challenges of Flexible Electronics

Over the past decade, the shift from rigid to flexible components represents a significant evolution in design and functionality. Over the past decade, the field of flexible electronics has grown from rudimentary printed conductors on pliable substrates to sophisticated sensors and digital circuits that perform practical applications. This progression is not merely a technical achievement but also a conceptual breakthrough, allowing electronics to be integrated into environments and objects where traditional, rigid circuits could not be used.

Initially, the development of flexible electronics focused on basic components such as conductors that were printed onto substrates capable of bending and twisting without losing functionality. This foundational work set the stage for more complex systems. Today, these flexible systems are being integrated into consumer products, such as advanced asset trackers in packaging, which monitor the condition and location of goods in transit. The potential applications are vast, ranging from health monitoring textiles to flexible displays and lightweight solar panels.

Challenges in Material and Design

However, the path forward is fraught with significant challenges that stem from the very nature of electronic component design and the materials traditionally used. Most electronic components are inherently rigid due to their operational requirements and the physical properties of the materials from which they are made. Silicon, for instance, is the cornerstone of modern electronics but is brittle and inflexible. Adapting these materials for use in flexible environments contradicts their fundamental design principles.

One of the primary challenges in the development of flexible electronics is maintaining the mechanical strength and durability of these devices. Flexibility often implies a susceptibility to wear and tear through repeated use. As these devices bend and flex, the materials and the embedded electronic components can degrade or fatigue over time, which poses a significant hurdle in terms of reliability and longevity.

Moreover, the compatibility of flexible materials with existing manufacturing technologies presents another significant challenge. The semiconductor industry is built around rigid materials, and most of its manufacturing processes are optimised for these materials. Developing new processes or adapting existing ones to accommodate flexible materials without compromising the efficiency and performance of the electronic components is a daunting task.

Semiconductor Limitations in Flexibility

In addition to these material and manufacturing challenges, there are also limitations related to the types of semiconductors that can be used in flexible electronics. Semiconductors are classified into p-type and n-type based on the type of charge carriers that dominate their electrical properties. Most flexible electronics today are limited to using n-type semiconductors because producing p-type semiconductors that are both flexible and effective has proven to be particularly challenging. This limitation restricts the complexity and efficiency of the circuits that can be created, as both p-type and n-type materials are necessary for building efficient and high-performance electronic devices.

Progress and Future Prospects

Despite these challenges, the progress in flexible electronics over the past decade has been impressive. The integration of these devices into consumer products is just the beginning. As researchers and engineers continue to tackle the fundamental challenges of material science, manufacturing processes, and semiconductor technology, the next generation of flexible electronics will likely be more durable, efficient, and ubiquitous.

PragmatIC Does it Again! Flexible RISC-V Processors That Could Cost Less Than $1

In a groundbreaking development in the field of electronics engineering, scientists have successfully created a flexible programmable chip that deviates from the traditional silicon-based design. This new innovation, the ultralow-power 32-bit microprocessor developed by U.K.-based Pragmatic Semiconductor and its collaborators, is capable of operating while being bent and can efficiently handle machine learning tasks.

Cost-Efficiency with IGZO Thin-Film Transistors

While silicon has long been the cornerstone of microprocessor technology, the high costs associated with its production, including capital expenses and chip packaging, have limited its applicability in cost-sensitive markets. The use of IGZO thin-film transistors (TFTs) as an alternative material helps overcome these barriers, offering a more environmentally friendly option that reduces carbon footprint and supports low-temperature manufacturing. This development could reshape the cost structure for microprocessor production, enabling more affordable solutions.

Remarkably, this chip, which utilises the open-source RISC-V architecture, is projected to cost less than a dollar, potentially transforming the market for wearable healthcare devices, smart packaging labels, and other cost-sensitive applications.

Furthermore, leveraging the open-source RISC-V instruction set architecture (ISA) eliminates licensing fees and minimises non-recurring engineering (NRE) costs, which are typically incurred with proprietary ISAs. This flexibility in customising processor features without additional costs positions the Flex-RV as a pivotal technology for low-budget applications.

Transformative Applications in Healthcare, Consumer Goods and Smart Labels

Emre Ozer, the senior director of processor development at Pragmatic, highlighted the practical applications of this technology. He explained, "We can develop an ECG patch that has flexible electrodes attached to the chest and a flexible microprocessor connected to flexible electrodes to classify arrhythmia conditions by processing the ECG data from a patient." This innovation signifies a major leap in medical technology, allowing for more versatile and accessible health monitoring solutions.

Beyond healthcare, flexible microprocessors like the Flex-RV hold the potential to be integrated into various fast-moving consumer goods, enabling smart labels that can monitor product conditions such as temperature and humidity. This integration could provide real-time data, enhancing supply chain transparency and efficiency, while maintaining a minimal production cost.

Innovations in Flexible Manufacturing and Design

The Flex-RV, as the device is named, is based on the metal-oxide semiconductor indium gallium zinc oxide (IGZO) and represents a significant shift from rigid to flexible electronics. This flexibility is achieved through the use of thin-film transistors that can be produced at low temperatures directly onto flexible plastics, considerably reducing manufacturing costs.

IGZO-based microprocessors have an added advantage: they do not require traditional chip packaging, which is essential for silicon-based chips to protect them from mechanical stress. This characteristic makes IGZO TFTs more suitable for flexible applications where resilience and adaptability are critical.

The choice of RISC-V for the instruction set—an open-source set introduced in 2010—further aids in minimising costs while allowing for greater customisation of the processors. This could democratise computing power, making it more accessible and versatile across various industries.

In addition, the programmability of the Flex-RV means it can be tailored to specific use cases without incurring significant development expenses. This ability to incorporate custom machine learning instructions enables it to perform tasks beyond conventional embedded systems, pushing the boundaries of what flexible processors can achieve in real-world applications.

Robustness Under Physical Stress: Power Efficiency Meets High Performance

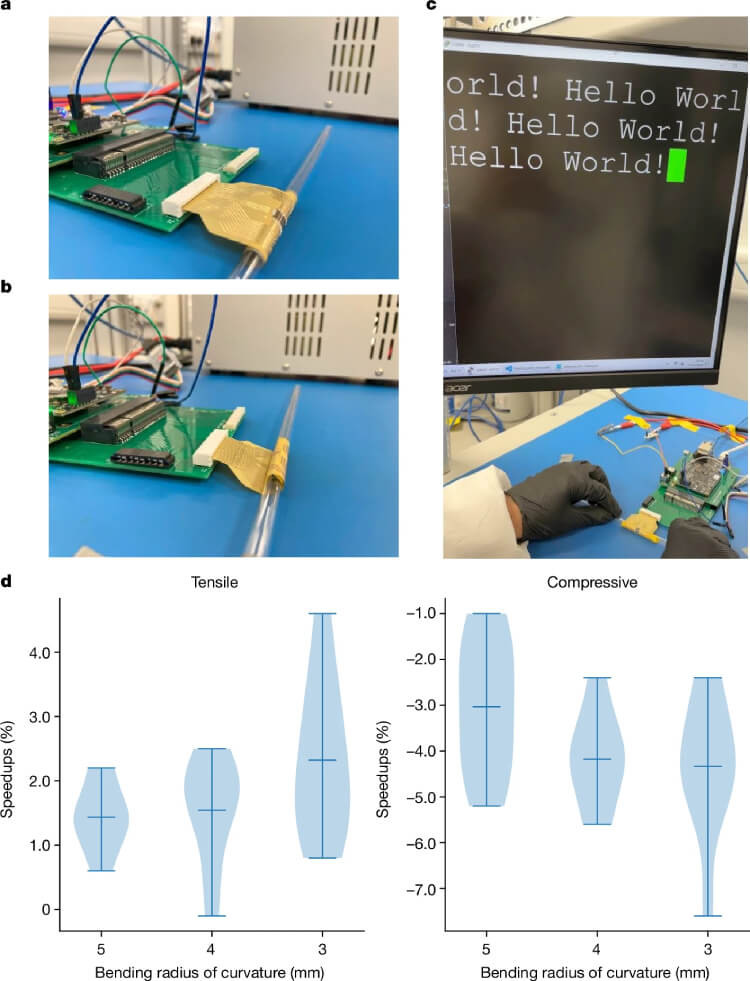

The Flex-RV microprocessor, tested on flexible printed circuit boards, exhibited the capability to function effectively when bent to a curve with a radius of 3 millimetres. This robustness in performance under physical stress is crucial for applications involving wearable or embedded flexible electronics.

This capability to maintain performance under mechanical stress was validated through extensive tests involving dynamic bending conditions. The tests demonstrated that the Flex-RV could operate seamlessly even when bent to radii as small as 3 millimetres, maintaining a consistent clock speed and minimal performance variation. Such attributes are essential for devices designed for active environments where physical flexibility is a necessity.

Moreover, the chip's performance, capable of running at 60 kilohertz while consuming less than 6 milliwatts of power, aligns well with the operational needs of various sensors used in emerging technologies like smart packaging and wearable health monitors.

Bridging Performance and Practical Applications

The development of flexible electronics has long promised a future where technology seamlessly integrates into our daily lives, from wearable devices to advanced industrial applications. With Pragmatic Semiconductor’s recent innovation—the Flex-RV microprocessor—this vision takes a significant step forward. Leveraging IGZO technology and the cost-effective RISC-V architecture, the Flex-RV exemplifies how engineering breakthroughs can drive down costs and enhance versatility. As flexible microprocessors gain traction, their potential impact on healthcare, AI, and consumer technology becomes even more profound.

This development not only pushes the boundaries of traditional computing hardware but also sets a new standard for the integration of electronics with everyday objects and devices, potentially leading to more innovative applications that blend technology seamlessly into our lives. The findings from this research were detailed in the journal Nature on September 25, marking a significant milestone in the field of semiconductor technology and opening new pathways for the future of electronic devices.

Future Implications for Industry and Logistics

The implications of this breakthrough extend to sectors like logistics, where smart tags equipped with flexible microprocessors can track and communicate the condition of items in transit. By incorporating Flex-RV into such solutions, industries could benefit from improved data accuracy and device longevity, thanks to the microprocessor’s robust and flexible design.

How Could Flexible Processors be Helpful for the Field of AI and Other Cutting-Edge Industries?

The unveiling of the Flex-RV, a flexible RISC-V 32-bit microprocessor, marks a significant milestone in the evolution of flexible electronics technology. This innovation not only showcases the advanced capabilities of current flexible circuits but also hints at the transformative potential of these technologies in various high-tech applications. The Flex-RV is particularly notable because it supports programming in high-level languages and offers reprogrammability, features that enhance its utility and adaptability across different platforms and applications.

The reprogrammability of the Flex-RV is a critical advancement. Traditionally, microprocessors were rigid, both physically and in terms of software adaptability. With the ability to be programmed in languages such as C, the Flex-RV breaks away from these constraints, offering a more versatile and user-friendly interface. This flexibility paves the way for developers and engineers to implement changes and updates without the need for extensive hardware modifications, which are costly and time-consuming.

Looking towards future applications, particularly in the field of artificial intelligence, the implications of such flexible processing units are profound. Imagine AI systems that are no longer confined to traditional hardware but can be incorporated seamlessly into everyday objects such as clothing or even organic structures within the human body. These processors could potentially transform how we interact with technology, making AI truly ubiquitous and integrated into our daily lives.

Transformative Impact in Healthcare

In the medical field, the integration of flexible, programmable microprocessors like the Flex-RV could lead to significant advancements in patient monitoring and treatment. For instance, these devices could be embedded into wearable fabrics that continuously monitor vital signs and adjust medical parameters in real time, providing personalised healthcare solutions that are both proactive and responsive.

Moreover, the inherent physical flexibility of devices like the Flex-RV offers enhanced durability and resilience in environments subjected to extreme conditions, such as vibrations and mechanical stress. This makes them ideal for use in industrial applications where traditional rigid electronics might fail. The capacity to flex and absorb such physical stresses without compromising functionality could extend the lifespan and reliability of devices used in such challenging environments.

Consumer Technology and Smartphones

The potential of flexible electronics extends beyond industrial and medical applications and into consumer technology. Smartphones, for instance, could undergo a complete transformation. The concept of a smartphone that not only bends but also rolls up or wraps around a limb could redefine portability and convenience. This level of flexibility would not only be a novelty but could lead to new ways of interacting with our devices and accessing information.

In the field of IoT, the deployment of flexible microprocessors like the Flex-RV could facilitate the development of innovative products such as "stick and stamp" devices. These devices, equipped with adhesive surfaces, could be attached to virtually any surface, expanding the IoT network and enabling a seamless collection and exchange of data across a multitude of environments. Such capabilities could enhance the functionality of smart homes, cities, and industries, ensuring more efficient operations and improved user experiences.

In Conclusion

The development of the Flex-RV microprocessor demonstrates the brilliance behind PragmatICs capabilities and how fast engineers have been able to the technology. This advancement not only broadens the horizon for current applications but also creates new possibilities in various fields, from healthcare to consumer electronics. As these technologies continue to evolve, they promise to further integrate into the fabric of everyday life, making electronic devices more adaptable, resilient, and seamlessly integrated than ever before.