AI Injects Steroids into the Circuit Design Process

Insights | 24-03-2025 | By Gary Elinoff

AI can Tame even the most Complex Circuit Designs, but only with Human Help.

Key Takeaways about AI Injects Steroids into the Circuit Design Process

- AI Circuit Design searches for solutions for design challenges similar to the one at hand.

- AI attempts to tackle design problems in a sequential basis, but is always ready for multiple iterations, to make design improvements based on knowledge gained.

- AI solutions are often somewhat probabilistic and can be based on what worked for similar design cases.

Introduction

Electrical engineers face many daunting challenges on the pathway to completing working circuit designs. Beyond arriving at the optimal schematic, they must also choose the best components, decide where on the board to place them and then attend to tracer design, routing and heat dissipation, among many other concerns. And, with increasing size and complexity of designs as well as increased performance requirements, the problems are only getting tougher.

To make matters worse, many design goals are contradictory, with designers running into ever increasing “whac-a-mole” situations. For example, increased clock speed causes a larger power drain, which in turn causes more heat to be generated. Increased heat needs to be dealt with, which may change the optimal placement and even component choices.

AI supercharges the circuit design process.

These problems portend a much longer design cycle, and can even result in overly expensive, suboptimal results. Indeed, the increasing complexity of modern designs make it hard for designers to negotiate the maze of choices successfully, and to avoid having the process fall into a hopeless state of anarchy.

Fortunately, for the mental health of engineering staff and for continued progress in the art and science of electronic design, AI, as it has in so many other fields of endeavors, has now come to the rescue. So let’s see how AI can help designers deal with their increasingly demanding task. And note that I described AI as helping designers, not replacing them, and as we’ll see, the probabilistic nature of AI solutions does present some limitations.

Supercharging Schematics and Choosing Components

It all starts with a schematic, but why reinvent the wheel when at least part of the solution is out there in the public domain? As described by Autodesk’s Edwin Robledo[1], AI will “By analyzing vast libraries of existing designs and performance data, AI algorithms can recommend component combinations that achieve desired functionalities with the highest efficiency. As a result, you will have circuits that consume less power, generate less heat, and minimize signal interference.”

Indeed, it is also possible to provide a detailed description of the design goals of the project, an AI can provide a baseline schematic.

You don’t have to go through ream after ream of data sheets to find the right components because they’re already online, and AI can do the leg work for you. Once you specify parameters, AI will bring you recommendations, which may include price, availability, and sources. Of course, these are only initial suggestions because subsequent choices may require changes later.

The next step is deciding where on the board to place those components.

Component Placement and Trace Routing

Before designing the electrical connections that marry the various components of a nascent design to their common purpose, the AI process has to decide just where to mount them. Factors that have to be considered include mounting components that have critical timing relationships; these may have to be mounted close to each other. Components that generate heat have to be mounted where that heat can be dissipated. Components that are either sensitive to EMI or capable of generating it have to “live” in a protected location. And, of course, manufacturability issues have to be taken into consideration.

Flux[2] describes how its Copilot AI system handles the task of routing for PCBs in an informative video. It’s a time consuming task, which Flux estimates to take up to 30% of total design time.

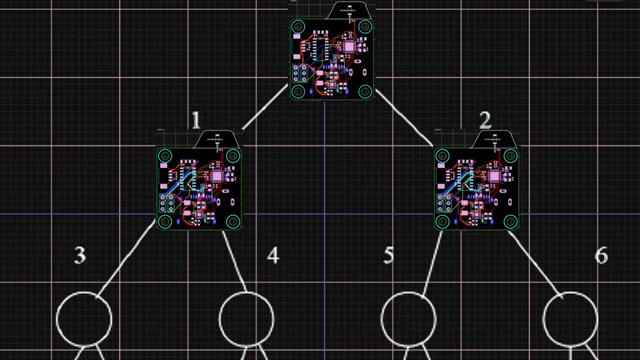

Classical auto routers only provide results based on the parameters the designer inputs. Flux’s AI methodology goes beyond the need for complex configuration inputs. Using Machine Learning (ML), the system is trained on a vast library of successful PCBs. The idea seems to be that if it worked once, maybe it’ll work again in what is judged to be a similar situation.

The system produces many potential designs, effectively creating a design decision tree, as illustrated below.

Image source. Flux Video (2:31)

An important step is to set rules and constraints, including trace widths, via types and clearances. Using Flux AI, a new rule set can be created from scratch, or an existing rule set from an earlier, successful design can be imported.

Sensitive signals involving power, high speed, and feedback traces are often manually routed by the designer. The system also provides special methods to make sure that, for example, inductors, often a source of EMI, are placed in locations where they aren’t likely to cause issues.

Problems Involved in Employing AI

It’s been emphasized throughout that one of the hallmarks of AI in circuit design is that solutions that might apply to the design requirements are simply lifted from the public domain and entered into the mix of possible and partial solutions. This “probabilistic” methodology isn’t acceptable in all cases.

Additionally, if the proposed design has to operate in unusual conditions, such as temperature extremes or an environment of high EMI or RFI, there may not have been a sufficient sampling of previous models to adequately address these challenges, and the efficacy of the resultant design may suffer.

There are also specific issues involved in the employment of AI in the design process, as enumerated by Actalent[3]. Some of these speedbumps are quite significant and rather surprising. They include:

- Regulatory Compliance and Certification. Some industries will require that the AI system employed in design overcome some difficult regulatory barriers.

- Data Privacy and Security. Third, AI solution providers must be vetted for security.

- Complex Design Constraints. AI designs may have difficulty adhering to unusual requirements.

- Interdisciplinary Collaboration. It will be challenging to effect collaboration between relevant electrical engineers, software developers, data scientists, and domain experts.

- Data Quality and Quantity.

- AI models require large, high-quality datasets for training. It may not always be possible to get sufficient relevant design samples.

AI-Based Circuit Design is an Iterative Process

Many of the commercial providers of AI technology emphasize the sequential nature of this new design process, starting with establishing a schematic and then moving on to component placement. However, as noted by EMSG[4]. “Getting an optimal PCB layout often requires many iterations of trial and error. Engineers may need to repeatedly adjust component placements and routing to meet design specifications, ensure signal integrity and manage thermal considerations. Each iteration cycle can prolong the design phase and increase development costs.”

However, this should not be regarded as a “negative” because as the design passes through its iterations, design rule checks and internal simulations will point to possible next steps.

AI-based circuit design doesn’t portend a one-stop solution. And, the design engineer, as well as the AI, are both deciders about what changes need to be made with every point of each go around. So while much of the drudgery and legwork previously required of the design engineer is eliminated, the need for human expertise is undiminished.

Wrapping Up

Design and test engineers will recognize many obvious similarities between AI based solutions and the EDA tools that they are already using. A schematic is generated, and then components are first chosen and placed and then routing is established.

And somewhere along the line, based on what is learned, a component is determined to be suboptimal or something else pops up. Then, the process may need to be restarted, but each necessary iteration will bring the process closer to the end result.

A big difference is that so much of the unpleasant groundwork, legwork and data entry are eliminated. And although in some situations this is problematic, the system can learn from solutions gleaned from the public realm, or from private corporate databases.

Challenges and Opportunities

A common complaint is the “opaqueness” of the AI decision making process. Humans are presented with solutions from the robotic gods, with no explanation of how these solutions were derived. Evidently many humans refuse to acquiesce, and demand to know how these conclusions were made, and to see many varied simulator runs to prove their effectiveness before doing even a trial real-world board or silicon run.

This is a particular issue for design situations that are subject to tough regulatory environments, such as those involving the notoriously litigious automotive healthcare fields. Solutions largely based on “it worked well in similar situations” may not be acceptable in these cases.

The only workaround for situations such as these is to look to AI only for possible solutions, circumstantial evidence if you will. Then, to do rigorous mathematical analysis for proof, backed up by extensive simulations.

References

- The Impact of AI on the Electronic Design Industry. Autodesk

- AI Auto Layout. Flux

- AI Implementation in PCB Layout Design. Actalent.

- How AI Is Changing Circuit Board Technology. EMSG.

Glossary of Terms

- EDA. Electronic design automation.

- Machine Learning (ML) allows computers to perform tasks without being explicitly programmed beforehand.