Best 3D Printer Features: What to Look for When Buying a 3D Printer

22-08-2019 | By Moe Long

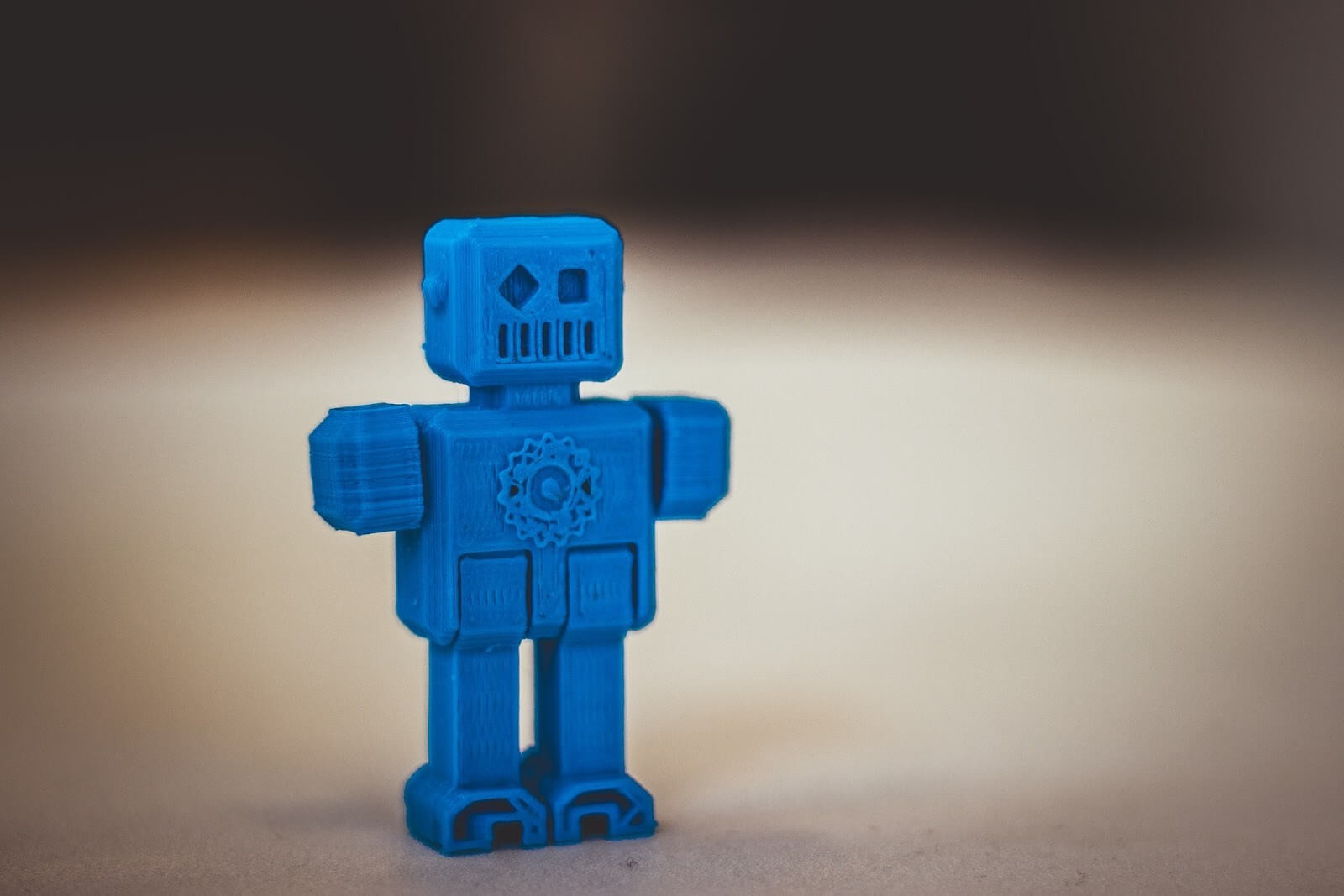

3D printing, and accordingly 3D printers, have exploded in popularity. While once these awesome gadgets were relegated to the most hardcore makers, increasingly affordable 3D printers and a slew of resources, from downloadable 3D printable files to 3D printing software, now the masses can enjoy 3D printing at home. However, as with virtually any purchase, and especially in the technology arena, you’ll want to focus on the right features. Learn what to look for in this 3D printer buying guide!

What to Look for When Buying a 3D Printer - Why Purchase a 3D Printer?

Though the price tag for even a budget 3D printer can be pretty steep, buying a 3D printer is worth it. Owning a 3D printer provides nearly limitless opportunity to create your household objects, from Raspberry Pi cases to napkin holders. You can create replacement parts for furniture, and extend the life of objects around your home.

Whereas normally you’ll need to either visit a maker space or order a print off of a website such as Thingiverse, now you can simply make your creations at home. You might even be able to make a bit of income by processing print jobs. Moreover, it’s simply fun. I have a blast with my Elegoo Neptune and Elegoo Mars printers, whipping up anything from chess pieces to a T-800 endoskeleton bust to sit under my computer monitor. Finally, it’s a fantastic learning opportunity. You’ll get hands-on with hardware and software, a better understanding of how.

Reasons to buy a 3D printer:

-

Monetary savings

-

Learning opportunities

-

Fun

3D Printer Buying Guide - What to Look for When Buying a 3D Printer

If you’re buying a 3D printer, there are tons of considerations. From resin vs. filament printers to self-levelling beds, these are the features you should look for when purchasing a 3D printer!

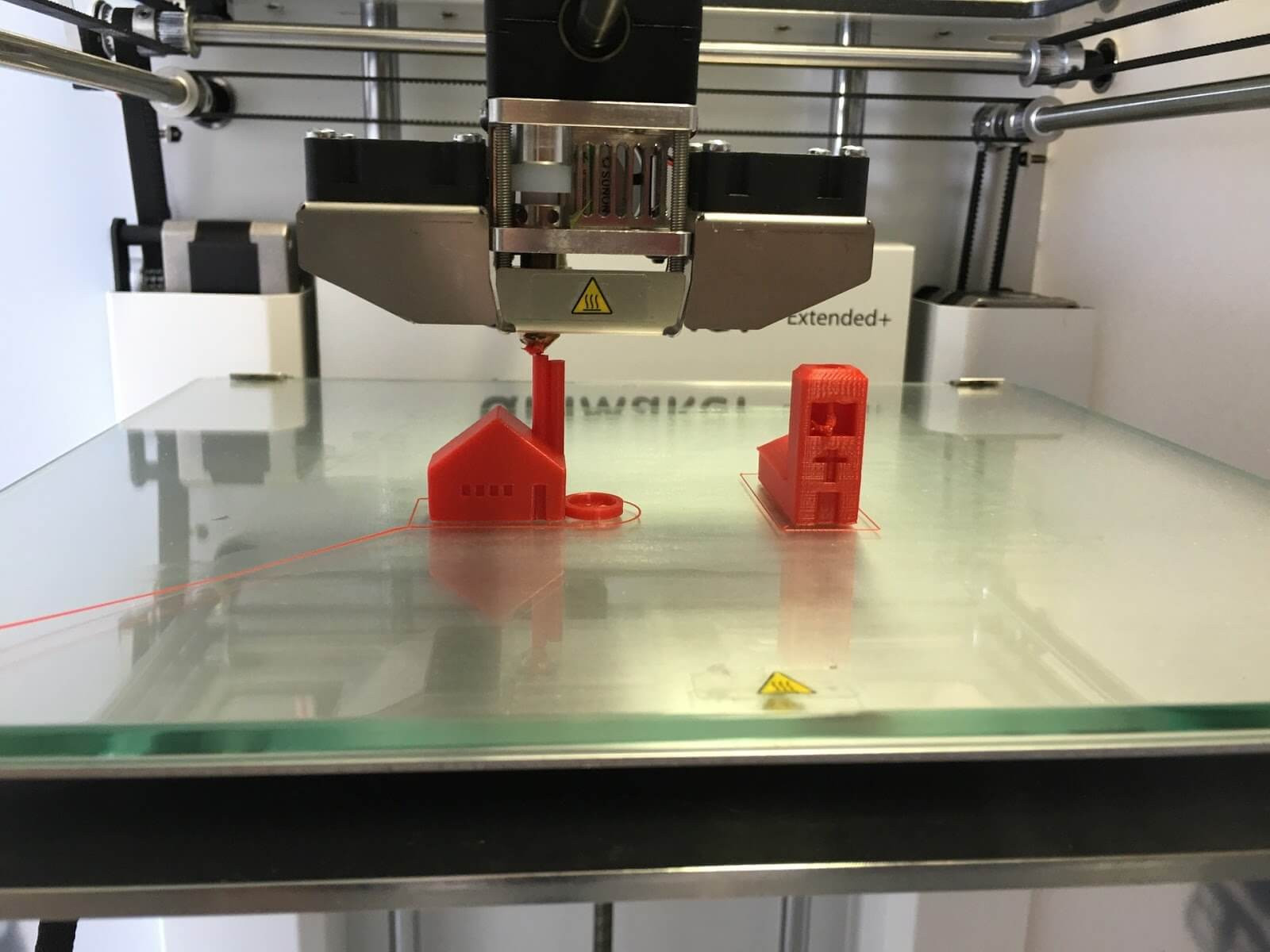

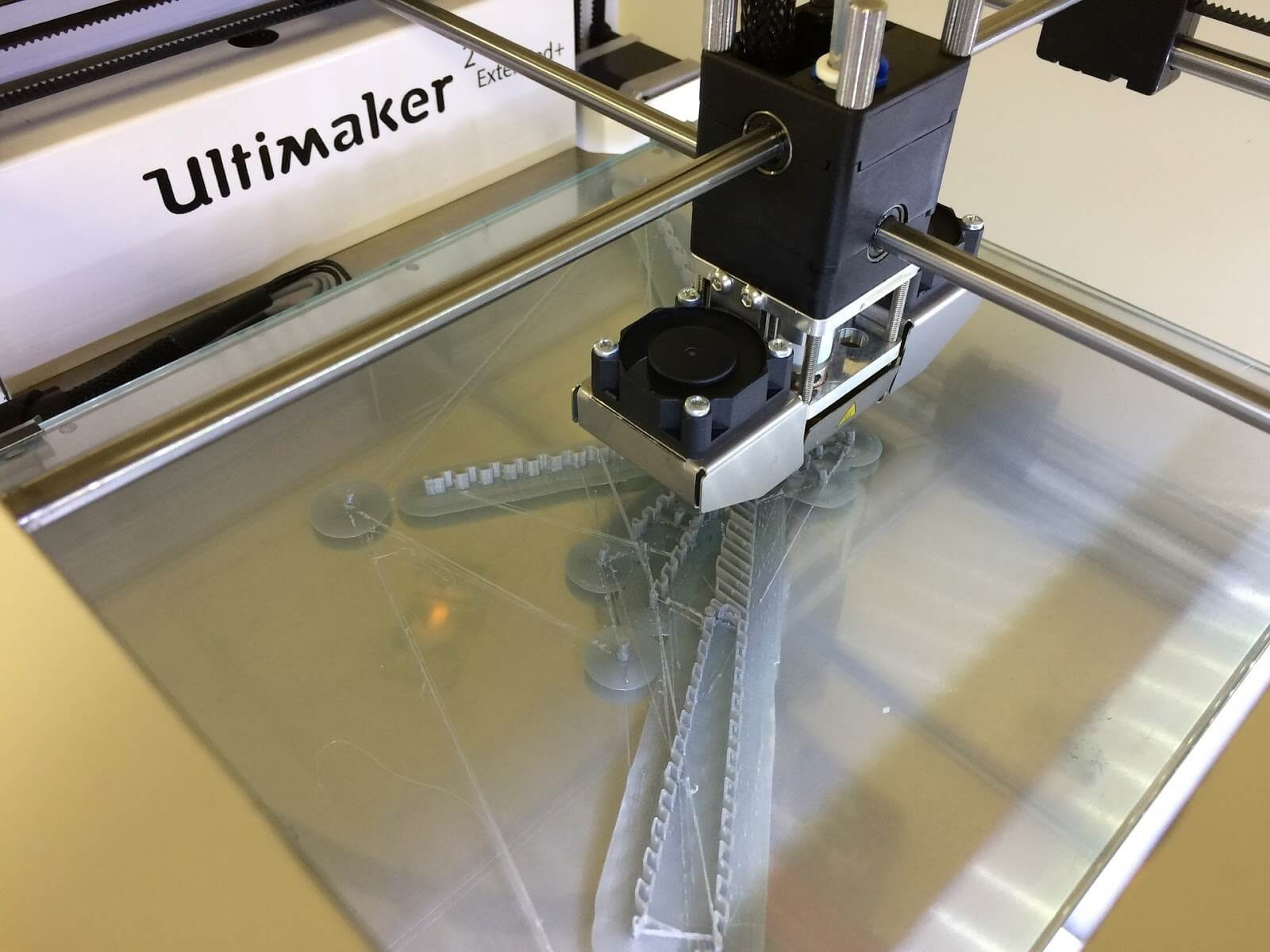

Resin vs. Filament 3D Printers

The first debate you’ll have is whether to opt for a resin or filament 3D printer. Both are excellent and should satisfy basic users. Generally, filament 3D printers are more common. FDM or fused deposition modelling printing melts down a string of plastic, known as filament. This filament gets melted and deposited through a HotEnd onto a bed. Then, the filament is added layer by layer until the final print is produced. When using an FDM printer, the material is deposited beginning with the bottom layer and builds up from there.

Resin printing, on the other hand, uses a liquid resin. The build plate lowers into a vat of resin and uses a light source to cure its liquid resin into layers. Resin printers boast better quality than their FDM printer counterparts, excelling with fine detail. However, this often comes at a price. Namely, monetary cost as well as messiness. Resin is pretty nasty stuff, making set up and clean up a chore. Moreover, resin printers are typically more expensive. Still, certain affordable resin printers are available.

3D Printer Noise

3D printer noise is a huge factor. No 3D printers are completely silent, but some remain quieter than others. Likewise, physical set up can contribute to the noise level. If you’re printing in your bedroom, 3D printer noise level plays a key role, especially since even a moderately-sized print can take the upwards of a few hours. Even if you’ve got a dedicated 3D printing area, 3D printing sounds can be heard around your home or by neighbours. Tricks such as placing your printer on a solid surface, on top of a yoga mat or carpet, and dampening surfaces help for 3D printer noise reduction.

Printing Speed

Speed of 3D printers varies. Typically, resin printers feature slower printing speeds than their FDM counterparts. If you’re merely printing for fun, speed might not matter quite as much. However, for business purposes, 3D printing speed may be more of an issue. For smaller print jobs, faster speeds don’t usually impact quality. But for larger prints, faster might come at the expense of fine details, and may even create problems such as vertical banding, or ringing. At the same time, too slow of a print could lead to stringing. Regardless, you’ll want a printer able to meet your desired printing speed requirements.

Self-levelling Bed

Among the most sought-after 3D printer features is a self-levelling bed. Manual bed levelling can be a right pain, a lengthy, frustrating process. An unlevel bed botches prints. Thankfully, many prints come with auto bed levelling features where a sensor tests various points on the print bed to best calculate the distance between the nozzle and print bed. Then, software adjustments ensure that the nozzle maintains the correct distance from the bed while printing. Although some users may prefer manual bed levelling, an auto-levelling 3D printer bed offers a fairly plug-and-print experience which massively streamlines the printing process. An auto-levelling bed is a great pick for 3D printing beginners.

3D Printer Connectivity Options

Before you print anything, you’ll need to send a 3D printable file to your printer. This can be accomplished through several methods. Most 3D printers feature a means of connecting via USB cable. Additionally, 3D printers commonly feature an SD card slot or USB port for plugging in a flash drive or SD card. My Elegoo Neptune comes with a USB bus as well as SD card slot whereas my Elegoo Mars resin 3D printer touts a USB port for printing straight from a flash drive.

Device Footprint and Build Size

While resin, filament, bed levelling, and print speed are all essential, you’ll want to think about how much physical space you’ve got. 3D printers come in all shapes and sizes, from mini 3D printers to industrial-sized behemoths. Tied pretty directly with device footprint, there’s build size. The 3D printing volume is the total maximum size of a print. Most resin printers carry a smaller build size than comparable filament-based 3D printers. For the average user, a moderate to smaller build platform should suffice. But for later prints, you’ll need to snag a 3D printer with a larger print volume, and even then you might have to print multiple pieces, then put everything together into a larger whole.

Print Quality, Accuracy, Precision, and More

Quality and accuracy of 3D prints are hugely variable. However, accuracy doesn’t necessarily translate to precision. You might find some printers are precise but inaccurate. While accuracy is a measure of hitting a target metric, precision focuses on determining repeated actions. So a printer may be accurate insofar as it hits close to the desired spot on a print bed, but imprecise insofar as it fails to consistently deposit in the same spot repeatedly.

Price

Finally, there’s the price. 3D printers, even budget devices, usually retail for hundreds of dollars. Nevertheless, there are loads of 3D printers under $500 which don’t compromise on quality. If you’re starting a 3D printer-centric business, such as selling 3D printed miniature figurines, consider upping your budget. But if you’re just getting a 3D printer for kicks, you might instead pick an affordable 3D printer.

3D Printer Buying Guide - Final Thoughts

Purchasing a 3D printer requires thinking about your specific use cases, preferences, and needs. Resin printers are often pricier than competing filament 3D printers but boasts better fine detail quality. However, they’re much slower than filament printers. Print volume, noise level, printing speed, and bed levelling mechanism rank among the most essential considerations. I prefer resin printers despite the messiness, smell, and slower speed. Quality of budget resin printers often surpasses that of mid-range to high-end filament printers. I’d recommend for filament printers snagging a unit with a self-levelling bed if possible, though many budget 3D printers come with a manual levelling print bed.

What features do you suggest looking for when selecting a 3D printer?