Mitsubishi Launch N-series 1200V SiC-MOSFET

02-07-2020 | By Robin Mitchell

This week Mitsubishi Electric have announced their latest range of SiC MOSFETs which offer lower power losses and higher tolerances to self-turn-on. What is SiC technology, and how does it benefit power applications?

SiC at a Glance

SiC is a semiconductor called Silicon-Carbide and is ideal for power applications. When compared to traditional silicon technology, SiC has a higher breakdown field enabling it to handle higher voltages per unit size, a higher thermal conductivity allowing it to more easily remove excess heat, and a higher energy gap. While the channel resistance in a SiC device is higher than that of Silicon, the higher breakdown voltage compensates for this with reduced transistor sizes allowing for smaller devices that have channel resistances on par with their larger silicon counterparts. SiC also allows for the creation of very high voltage power MOSFETS useful in applications that traditional Silicon would struggle in. Such examples of applications include advanced power switching systems combining both AC and DC, electric vehicles which have large battery packs and current demands, and motor control systems that require speed control utilising bridges. However, because SiC is not as widespread as Silicon, it is more expensive to incorporate into designs meaning that designers have to be sure that traditional silicon devices cannot be utilised.

Mitsubishi Announces N-Series

To continue the push towards SiC power devices, Mitsubishi has announced its latest N-series range of SiC-MOSFET devices.

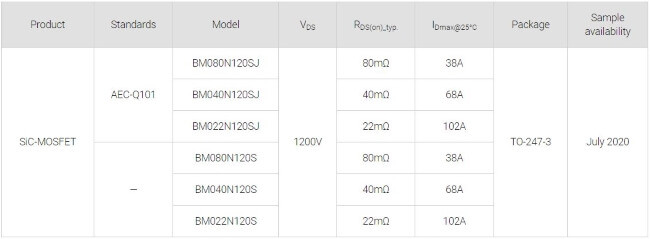

These power transistors are rated for up to 1200V that feature low power losses and high tolerance to self-turn-on. The new range of devices is being aimed at applications which need to minimise power consumption as well as reduce the overall size of a power supply system. Such applications include electric vehicles, charging systems, photovoltaic power distribution, high voltage conversion, and power switchers. The N-series incorporate new doping technologies that help to reduce overall switching loos and on-resistance. The result of this technology is an industry-leading figure of merit of 1,450mΩ and an overall power supply energy reduction of 85% when compared to standard Si-IGBTs. The N-series also reduces mirror capacitance which helps to improve the N-series resistance to self-turn-on by up to 14 times. This enables for faster switching and thus a reduction in power consumption. So far, 6 devices have been named in the N-series, with three being AEC-Q101 qualified. All devices in the range have a maximum VDS of 120V with on resistances ranging between 22mΩ to 80 mΩ and drain currents from 38A to 102A. All devices are packaged in a TO-247-3 for maximum heat dissipation and current capability with samples available by July 2020. The new devices will be demonstrated at exhibits in major trade shows, including PCIM Asia 2020 in Shanghai from November 16th to 18th.

Conclusion

The new range of SiC MOSFETs developed by Mitsubishi demonstrates the move away from traditional semiconductor materials such as Silicon in the power industry. While SiC is great for power applications, it is very unlikely to ever replace Silicon in information processing such as DSPs, FPGAs, or processors due to Silicon’s maturity and advantages in high-speed electronics. SiCs may be expensive, but they offer designers with power solutions that Silicon could never achieve.