Successfully Outsourcing Electronics Manufacturing

16-05-2024 | By Seb Springall

When properly executed, outsourcing manufacturing provides Original Equipment Manufacturers (OEMs) with a wide variety of commercial benefits. In contrast, if the subcontracting process goes wrong, it may do harm to an OEM's business operations and reputation.

Benefits of Outsourcing

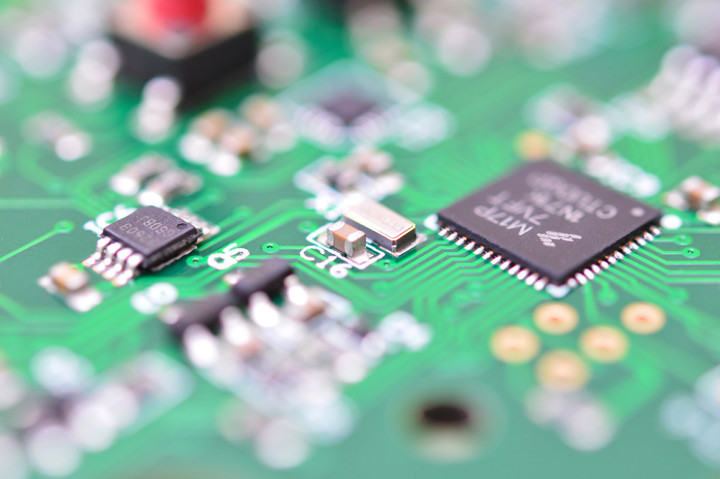

The electronics industry evolves rapidly, with components becoming increasingly smaller and more complex. Manufacturing printed circuit board assemblies (PCBAs) requires highly sophisticated equipment, demanding substantial capital investment. By partnering with a Contract Electronics Manufacturer (CEM), OEMs can avoid the need to install, maintain, and update costly production equipment and the overheads associated with running these production lines.

CEMs that provide single-source supply, including component procurement, provide significant advantages to OEMs. Single-source supply reduces the need to purchase from various vendors, manage logistics for timely component delivery, and ensure individual component quality control. CEMs frequently have strong ties with dependable supply partners and distributors, and they generally acquire components for several clients, allowing OEMs to benefit from the cost reductions associated with the CEM's increased purchasing power.

Contracts and Service Level Agreements (SLAs), which include fixed pricing and supply arrangements tailored to the OEMs' requirements, can protect OEMs against price fluctuations in the electronic component market and ensure a reliable long-term supply.

Risks of Outsourcing

While OEMs can reap significant benefits from selecting the right CEM partner and outsourcing electronics assembly, the process carries inherent risks. The most critical risk is underestimating the upfront effort required to select a CEM and provide the detailed information necessary for the successful production of a high-quality product. Although outsourcing can yield long-term benefits, it demands substantial effort from OEMs during the initial phases. An excellent CEM will not just ‘build-to-file’ but will thoroughly review customer data, ask pertinent questions, and offer cost-saving and critical design-for-manufacture (DFM) recommendations.

Timing is crucial when transitioning from one supply route to another. If mishandled, OEMs risk production line stoppages (if the subcontracted part is a sub-assembly) and end-product shortages. A CEM should understand this delicate balance and collaborate closely with an OEM to ensure a seamless transition.

For products in production for some time, OEMs often accumulate knowledge of past quality issues and implement processes to address them. Unless this information is well-documented and communicated to the CEM, there is a risk of old quality issues resurfacing.

OEMs may also worry about exposing valuable intellectual property to a third party. A reliable CEM should provide assurances about handling sensitive data and typically will enter into a legally binding non-disclosure agreement (NDA).

Finding the Right CEM

Given the discussed risks and benefits, how should OEMs find and build a successful partnership with a new CEM? Here is a straightforward strategy to help you begin the process:

Establish Your Requirements

Clearly define your requirements before searching for a new manufacturing partner. Different CEMs offer varied capabilities, service levels, and capacities. What processes are you considering subcontracting? What volumes do you plan to order once confident in the supplier’s performance? What internal procedures must the new supplier have in place? What supply model fits your business needs? What quality accreditations are essential? Should the supplier be in a specific geographical location?

Analyse the Risks

Evaluate all potential risks associated with transferring processes to a new supplier. Have you faced specific difficulties with component sourcing, assembly processes, or quality issues that could reoccur? Are there possible supply gaps that could affect your business or customers? Spend time on this phase and develop robust plans to mitigate perceived risks.

Search for a CEM

With your requirements and risks understood, start your search. Online tools provide a good starting point. Review industry publications for adverts, listings, and content from potential suppliers. Attend industry events and exhibitions to meet potential manufacturing partners in person, which is invaluable. Speak to industry peers and consider their recommendations.

Conduct Background Research

Understand the long-term security offered by prospective manufacturing partners. Check the company’s history and financial records, using resources like Companies House online service.

Ask the Right Questions

Narrow your selection by contacting potential partners and asking pertinent questions. What quality accreditations do they hold? What manufacturing, inspection, and test equipment do they use? Do they manufacture locally or offshore? What KPIs do they monitor and how are they performing? What services do they offer beyond your immediate requirements?

Meet Face-to-Face (or via Video Conferencing)

Long-term business partnerships require understanding to see whether you can work collaboratively with a prospective supplier. Meet the management team and key employees. Assess the company’s culture and how it aligns with yours. If an in-person visit isn’t possible, conduct video conferences and meet the essential personnel.

Request for Quote (RFQ)

Provide potential suppliers with a detailed RFQ, including all the information needed to accurately quote and successfully manufacture your product. This may include projected production quantities, Bill of Materials, PCB artwork files, mechanical assembly drawings, programming and test instructions, and specific assembly standards.

Conduct an Audit

Audit prospective CEMs to understand their processes thoroughly. How are quotes and orders handled? What purchasing procedures do they follow? How are suppliers qualified? Ensure inspection and test results are recorded and equipment calibration is controlled. Confirm staff training to appropriate standards and traceability throughout the manufacturing process. If possible, visit the CEM or use video conferencing for a live tour.

Establish a Contract

A robust supply contract benefits both parties. Consider contracted pricing, buffer stock agreements, supply schedules, returns procedures, and service levels crucial for smooth business operations.

Carefully Ramp Supply

Apply the rule of ten with new suppliers: start with small quantities and increase gradually. Identifying and solving process and quality issues before full-scale manufacture is essential. A good CEM will ensure procedures are in place to guarantee high-quality, on-time delivery.

Starting Your Search

Understanding the risks and benefits of outsourcing to a new CEM and following the strategy outlined above, consider starting your search with Corintech.

Corintech.com

sales@corintech.com

+44 (0)1425 655655