The Role of Procurement in a Circular Supply Chain Model

18-09-2024 | By Liam Kilmister

Component Sense is a leading electronics redistribution company. By specialising exclusively in excess and obsolete electronic components, we help electronic manufacturers reduce waste, recoup costs, and contribute to a circular economy.

The Role of Procurement in a Circular Supply

Procurement professionals and component buyers have a significant role to play in promoting a truly circular electronics industry. Decisions made at the procurement stage can significantly impact a product and its manufacturer's environmental/carbon footprint.

Sixty-two million tonnes of electronic waste (e-waste) was created in 2022, an increase of 82% since 2010 [1]. While some may see recycling as the solution to the ever-growing mound of disposed electronics, it often involves high energy requirements and has environmental implications.

Circularity in electronics goes beyond recycling. For procurement experts, circularity means taking a holistic approach to sourcing, looking beyond budget considerations, and instead considering the impact of their procurement on their company, communities, and environment.

What is a circular supply chain?

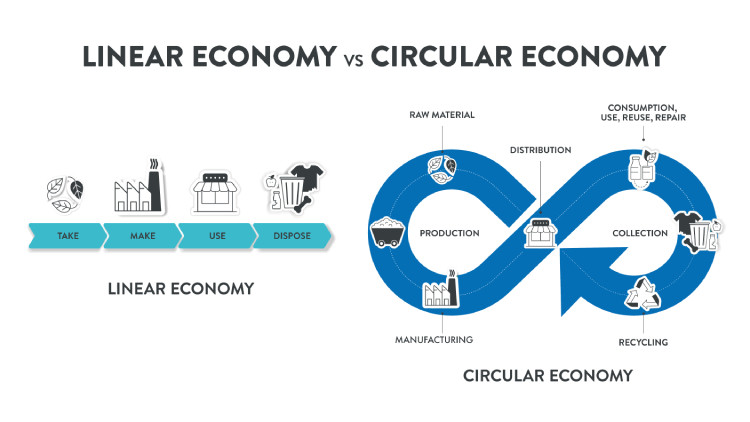

A linear supply chain model follows an unsustainable take, make, and dispose methodology. In contrast, a circular supply chain generally follows a take, make, use, collect, refurbish, redistribute, and recycle approach.

Circularity in electronics means eliminating waste and maximising the lifetime value of materials. This is achieved by repairing and refurbishing products, redistributing unused components, and recycling or scrapping only as a last resort.

Considering the entire lifecycle of components is essential to slowing and narrowing resource loops. Therefore, the way components are sourced can greatly influence a company's overall sustainability merits. In addition to reducing the environmental footprint, circularity also strengthens supply chain resilience.

Choosing suppliers

An electronic manufacturer can only claim to contribute to a circular economy if it practices sustainable procurement. When choosing suppliers, part buyers should insist on full traceability. This ensures full visibility, that raw materials are ethically sourced, and that carbon emissions and waste are minimised during delivery.

Luckily, many companies now publish their operations' environmental and social impact. This helps procurement professionals evaluate options and assess their sustainability and financial implications. Large customers can also leverage their buying power to encourage their suppliers to foster more sustainable practices.

Turning to secondary market suppliers is another way procurers can contribute to circularity. While the grey market may sometimes have a bad reputation due to some untrustworthy sellers and the occasional presence of counterfeit goods, the reality is not black and white.

Taking the time to vet secondary market suppliers protects buyers, ensuring they purchase fully traceable, brand-new parts. These parts would otherwise be scrapped in most cases.

Leveraging digital tools

AI and blockchain technologies are making it easier than ever for procurement experts to have full visibility of their supply chain and operations. Such tools allow more accurate component demand forecasting and the ability to stay ahead of market trends and disruptions. Ultimately, utilising digital tools like these also helps companies reduce e-waste.

AI-powered platforms for BOM (bill of materials) matching make it easier for procurers to buy sustainably. These platforms allow buyers to match their BOM lists with fully traceable, repurposed components from the secondary market.

Considering emissions

Where components come from and how they are transported are vital considerations for sustainably-minded procurement professionals. Transportation accounts for a large portion of the emissions from the global supply chain. It is no surprise that more electronic manufacturers are considering nearshoring and local suppliers.

Given their relative carbon efficiency and cost, shipping vessels handle 80% of global trade [2]. However, many current ships are still powered by fossil fuels. When sourcing components, the eco-friendliness of the shipping method should be a priority. Procurers should opt for shorter delivery routes and electrified vehicles where possible. In shipping, slow steaming and sharing container space could also be explored where possible.

Carbon emission reporting and carbon offsetting are other practices that could be prioritised when choosing a supplier. Initiatives like One Tree Planted have led companies to partner in global reforestation efforts to offset their carbon emissions.

Prioritising redistributed components

One of the most effective ways procurement experts can contribute to circularity with their buying power is by prioritising redistributed excess and obsolete components.

The process of extracting raw materials and producing new components consumes significant energy and causes pollution. Purchasing untouched inventory on the secondary market reduces the demand for new parts and decreases e-waste.

Companies like Component Sense redistribute unused, fully traceable components from large OEMs (original equipment manufacturers) and EMSs (electronic manufacturing services). This ethos, coupled with a robust quality inspection process, removes the risk of counterfeits and promotes a circular supply chain.

'Secondary market components are a win-win. The parts are kept in a circular supply chain, and this reduces the need for new resource extraction. Redistribution also recoups valuable funds for electronic manufacturers,' explained Component Sense Sales Director, Rose McGee.

Conclusion

While recycling is an important part of a circular economy, reuse and redistribution should take priority. Only 1% of the world's demand for REEs (rare earth elements) is met by e-waste recycling [3]. After all, a key principle of circularity is extending the lifetime value of materials for as long as possible.

A proactive approach to sustainable sourcing can significantly reduce a manufacturer's overall environmental footprint. This strategy early on, coupled with ensuring any excess obsolete parts are not scrapped but instead redistributed further down the production line, contributes positively to ESG (environmental, social, and governance) efforts.

Looking ahead, it is expected that digital tools, the growth of the safe secondary market, and increased sustainability regulations will push electronic manufacturers to contribute to a circular economy even more. Getting ahead now will secure your position as a market leader and inspire lasting change.

References

- [1] https://unitar.org/about/news-stories/press/global-e-waste-monitor-2024-electronic-waste-risi ng-five-times-faster-documented-e-waste-recycling

- [2] https://unctad.org/topic/transport-and-trade-logistics/review-of-maritime-transport

- [3] https://unitar.org/about/news-stories/press/global-e-waste-monitor-2024-electronic-waste-risi ng-five-times-faster-documented-e-waste-recycling