Biodegradable Smart Textile Reduces E-Waste in Wearables

31-01-2025 | By Robin Mitchell

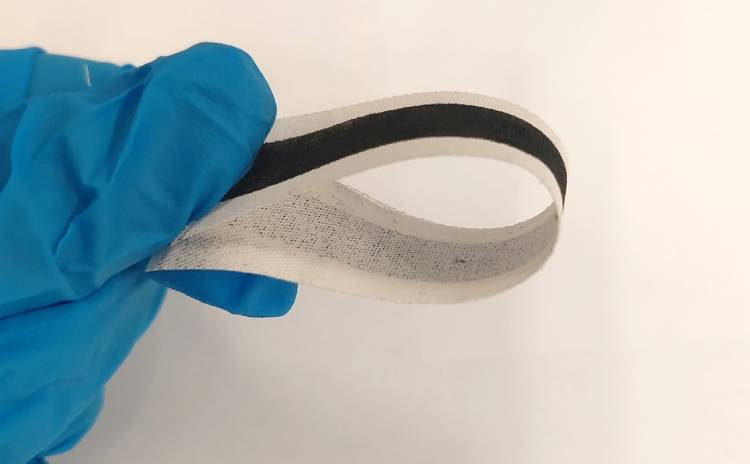

A segment of e-textile showcasing the flexibility of inkjet-printed graphene. Credit: Marzia Dulal

While flexible electronics hold immense promise for transforming wearables, they also face a host of challenges—ranging from rigidity and fragility to environmental impact and manufacturing difficulties. Recently, a research team from the University of Southampton and UWE Bristol has unveiled a fully inkjet-printed, biodegradable electronic textile that may offer a way forward.

Key Things to Know:

- Researchers from the University of Southampton and UWE Bristol have developed SWEET, a fully inkjet-printed, biodegradable electronic textile designed for sustainable wearable technology.

- SWEET textiles integrate graphene and PEDOT:PSS for enhanced conductivity, durability, and flexibility, making them ideal for medical and wearable applications.

- Unlike conventional e-textiles, SWEET materials decompose in soil within months, significantly reducing electronic waste and environmental impact.

- The use of inkjet printing instead of traditional manufacturing processes minimises material waste, energy consumption, and water usage while enabling scalable production.

What hurdles do these next-generation devices still encounter, what exactly have the researchers developed, and what might this eco-friendly material mean for the future of wearable technology?

The Challenges Of Modern Flexible Electronics

The swift advancement of technology has led to the development of numerous electronic devices that have reshaped our daily lives. From smartphones to laptops, these devices have become an essential part of our daily routines, offering us endless possibilities and convenience. However, as technology continues to develop, the need for more advanced and adaptable electronic devices has become increasingly evident. The rise of wearable devices, flexible displays, and smart textiles has marked a new era in the field of electronics, with flexible electronics at the forefront of this shift.

The Rise of Flexible Electronics in Wearable Technology

Flexible electronics, as the name suggests, are electronic devices that can be bent, folded, and manipulated without compromising their functionality. These devices have the potential to alter numerous industries, including healthcare, fashion, and technology, by providing users with a more comfortable, convenient, and connected experience. For instance, wearable devices that integrate flexible electronics can monitor vital health signs, such as heart rate and blood pressure, while smart textiles can enable clothing to communicate with other devices, changing the way we interact with technology.

However, despite the numerous benefits offered by flexible electronics, they still face several challenges that hinder their widespread adoption. One of the primary challenges faced by flexible electronics is their inherent rigidity. Traditional electronic components, such as silicon chips and circuit boards, are designed to be rigid, providing a stable platform for electronic circuits. However, these components are not suitable for flexible electronics, which require materials that can bend and flex without compromising their functionality.

The rigidity of traditional electronics is due to the materials used in their construction. Metals, ceramics, and other substances are commonly used in the production of electronic components, but these materials are not flexible by nature. As a result, the transition from rigid to flexible electronics is not a straightforward process. The limitations of current manufacturing processes also hinder the development of flexible electronics, making it challenging to produce devices that are both flexible and functional.

In addition to rigidity, flexible electronics also face challenges related to fragility and limited mechanical flexing. While flexible components can be designed to be flexible, they often lack the durability and mechanical strength required for long-term use. The repeated bending and flexing of these components can lead to fatigue, resulting in cracks, tears, or breakages. This fragility affects not only the performance of the device but also its lifespan, making it challenging to design flexible electronics that can withstand mechanical stress over time.

Limited Bendability and Its Impact on Device Longevity

The limited bendability of flexible electronics is another challenge that hinders their widespread adoption. Most flexible electronics can only tolerate a limited number of bends before failing, reducing their practicality for long-term use. This limitation is due to the mechanical properties of the materials used in their construction, which can only withstand a certain degree of bending and flexing. As a result, flexible electronics often require additional design solutions to enhance their durability and flexibility, which can compromise their performance and cost-effectiveness.

The limited functionality of flexible electronics is another challenge that hinders their adoption. Most flexible electronics currently lack the processing power, energy efficiency, and other capabilities of traditional rigid devices. The miniaturisation of processing components without sacrificing performance is a challenge in the development of flexible electronics. The use of compact, less efficient batteries that are harder to integrate with flexible designs also hinders the development of flexible electronics with advanced capabilities.

Environmental Impact and Sustainability Challenges

The environmental impact and disposal concerns associated with flexible electronics are another challenge that hinders their adoption. The use of non-biodegradable materials in flexible electronics poses environmental risks, including the contamination of soil and groundwater. The rapid obsolescence of flexible electronics also contributes to the growing problem of electronic waste (e-waste), which is difficult to recycle and dispose of properly. The lack of efficient recycling infrastructure for flexible electronics exacerbates this issue, making it challenging to develop sustainable and environmentally friendly flexible electronics.

Researchers Develop Flexible Biodegradable Smart Textile

In a new breakthrough that could change the face of wearable electronics, a team of researchers from the University of Southampton and UWE Bristol have successfully developed a fully inkjet-printed, eco-friendly electronic textile. The new fabric, dubbed SWEET (Smart, Wearable, and Eco-Friendly Electronic Textiles), has been shown to be both sustainable and biodegradable, paving the way for a new era of wearable technology.

According to the researchers, the new textile is designed to be durable, safe to wear, and comfortable, while also being kind to the environment when no longer required. The team's design consists of three layers, including a sensing layer, an interface layer for the sensors, and a base fabric made from Tencel, a textile that is both renewable and biodegradable.

Tencel: A Renewable and Biodegradable Smart Textile Base

Tencel, a fibre derived from wood pulp, has been gaining traction in the textile industry for its sustainability and moisture-wicking properties. Unlike synthetic alternatives, which can contribute to microplastic pollution, Tencel is fully biodegradable and decomposes without leaving harmful residues. The use of such materials in smart textiles represents a shift towards reducing the carbon footprint of electronic wearables, a growing concern in an industry facing scrutiny for its environmental impact.

To validate its effectiveness, researchers tested the SWEET textile on multiple volunteers, measuring heart rate and temperature with industry-standard accuracy. The image below captures one of the lead researchers, Marzia Dulal, conducting live tests to assess the textile’s real-time sensing capabilities.

PhD researcher Marzia Dulal evaluating the sensing capabilities of the e-textile. Credit: Marzia Dulal

These results underscore the potential of SWEET technology in wearable medical applications, paving the way for seamless integration into future health-monitoring devices.

The active electronics in the design are made from graphene and a polymer called PEDOT:PSS, which are precision inkjet-printed onto the fabric. The researchers have demonstrated the effectiveness of the new textile by using it to monitor heart rates and temperatures in five volunteers. The results showed that the material can reliably measure both heart rate and temperature at industry-standard levels.

Graphene and PEDOT:PSS: Advancing Conductive E-Textiles

Graphene’s inclusion in e-textiles marks a significant step forward in developing conductive, lightweight, and highly durable materials. Recognised for its exceptional strength-to-weight ratio and superior electrical conductivity, graphene-based electronics offer improved signal reliability compared to traditional metal-based conductive fibres. Additionally, the integration of PEDOT:PSS enhances the textile’s flexibility, ensuring that it remains comfortable and responsive when worn.

SWEET's Biodegradability: Tackling E-Waste Challenges

A key advantage of SWEET textiles is their biodegradability. The image below showcases the different layers of the e-textile after four months of decomposition, revealing a significant reduction in material mass and strength.

Various layers of the e-textile following four months of decomposition. Credit: Marzia Dulal

This breakthrough helps address one of the biggest challenges in the electronics industry—e-waste disposal—by offering an environmentally friendly alternative that naturally decomposes over time.

But what makes the new textile truly revolutionary is its ability to decompose when disposed of. The researchers buried samples of the fabric in soil to test its biodegradable properties and found that after four months, the fabric had lost 48% of its weight and 98% of its strength. This suggests that textiles can rapidly decompose, reducing the amount of waste generated by the electronics industry.

The decomposition rate of SWEET textiles is a promising advancement, especially when considering the growing problem of e-waste. According to recent research, electronic waste accounts for over 50 million tonnes annually, with less than 20% being properly recycled. SWEET’s biodegradable nature aligns with global sustainability initiatives aimed at reducing landfill accumulation and promoting circular economy models in electronics manufacturing.

The researchers also conducted a life cycle assessment to determine the environmental impact of the new textile. The results showed that the graphene-based electrodes had up to 40 times less impact on the environment than traditional electrodes. The use of inkjet printing instead of screen printing also reduces material waste, energy consumption, and water usage.

Inkjet Printing: A Low-Waste Manufacturing Solution

Inkjet printing technology further reinforces the sustainability of SWEET textiles by minimising excess material deposition, a common drawback of traditional screen-printing methods. Unlike conventional techniques, which require extensive rinsing and often involve hazardous chemical processes, inkjet printing ensures precise deposition, eliminating unnecessary waste. Additionally, studies have demonstrated that inkjet-printed conductive textiles retain their performance even after multiple wash cycles, proving their viability for long-term use.

According to the researchers, the new textile has the potential to reshape the wearable electronics industry, particularly in the area of early detection and prevention of heart diseases. The team hopes to move forward with the design to create wearable garments that can monitor vital signs and provide early warnings for potential health issues.

While the new textile is still in its early stages of development, it has the potential to revolutionise the way we think about wearable electronics. The ability to create sustainable and biodegradable textiles could help reduce the environmental impact of the electronics industry while also providing new opportunities for wearable technology.

Future Applications: From Wearables to Medical Innovations

Future applications of biodegradable smart textiles could extend beyond wearables into healthcare and environmental monitoring. Researchers are already exploring their potential in biosensing applications, where integrated sensors could track real-time physiological data, including hydration levels, stress indicators, and even early signs of infection. By combining sustainability with next-generation health monitoring, SWEET textiles could redefine the intersection of medical technology and eco-conscious innovation.

Does This New Material Solve The Many Challenges Faced?

While the development of SWEET technology is certainly exciting, whether or not it is able to solve the many challenges faced by wearable electronics is yet to be determined.

With regards to long-term reliability, the results of the tests demonstrated that SWEET technology is not only able to withstand repeated stretching but also retains its electrical properties, making it an ideal material for long-term wearable devices. The importance of durability in wearable devices cannot be overstated, as devices that are prone to breaking or tearing can be both uncomfortable and unreliable. Furthermore, the use of durable materials in wearable devices can also help to reduce electronic waste, as devices are less likely to be discarded prematurely.

Sustainability and Biodegradability: Reducing E-Waste

The environmental impact of wearable electronics is also a major concern, as traditional e-textiles have been made from non-biodegradable materials, which can have harmful effects on the environment when discarded. SWEET technology, however, has been designed with sustainability in mind, utilising biodegradable materials such as Tencel and graphene. The use of biodegradable materials not only reduces the environmental impact of SWEET technology but also makes it non-toxic, meaning that it can be safely discarded without causing harm to the environment. Additionally, SWEET technology is also compostable, making it an ideal material for use in smart textiles that need to be replaced regularly.

Energy-Efficient Manufacturing with Inkjet Printing

In addition to its environmental benefits, SWEET technology also has a number of manufacturing advantages. Traditional manufacturing processes for e-textiles can be highly energy and resource-intensive, making them costly to produce. Furthermore, the use of toxic chemicals in traditional manufacturing processes can also make them harmful to the environment. SWEET technology, however, utilises an inkjet printing process that is not only more efficient but also produces less waste. The use of an inkjet printing process also makes SWEET technology highly scalable, allowing for mass production without the need for expensive equipment. This not only makes SWEET technology more cost-effective but also reduces the environmental impact of its production process.

Medical Applications: Advancing Health Monitoring

One of the most promising applications for SWEET technology is in the field of medical devices. The ability of SWEET technology to monitor vital signs such as heart rate makes it an ideal material for use in wearable medical devices. Additionally, the use of biodegradable materials in SWEET technology also makes it ideal for use in medical applications, as it can be safely discarded without causing harm to the environment. Currently, SWEET technology is being used in heart rate monitoring and vital sign tracking, but further testing is needed to determine its accuracy and reliability in real-world applications. However, the promising results of SWEET technology make it an exciting area of research, and it is likely that SWEET technology will play a major role in the development of future wearable devices.

To sum up, SWEET technology is a promising development in the field of wearable electronics, offering a number of advantages over traditional technologies. The durability of SWEET technology makes it ideal for use in long-term wearable devices, while its use of biodegradable materials makes it an environmentally friendly option. The inkjet printing process used to manufacture SWEET technology also makes it highly scalable, allowing for mass production without the need for expensive equipment. As research into SWEET technology continues, it is likely that it will play a major role in the development of future wearable devices and may even be used in medical applications.