Unlocking the Possibilities of Programmable Logic

10-02-2025 | By Jack Pollard

Article by Russell Crane - Product Marketing Engineer of Programmable Logic Devices, Texas Instruments

Programmable logic devices (PLDs) play a crucial role in modern electronics, enabling engineers to integrate logic functions while reducing board space and costs. While traditional logic devices remain widely used, evolving design complexities and tighter integration requirements are driving the adoption of PLDs, complex PLDs (CPLDs), and field-programmable gate arrays (FPGAs). These solutions help optimise supply chains, lower manufacturing costs, and speed up time to market.

Programmable logic devices (PLDs) play a crucial role in modern electronics, enabling engineers to integrate logic functions while reducing board space and costs. While traditional logic devices remain widely used, evolving design complexities and tighter integration requirements are driving the adoption of PLDs, complex PLDs (CPLDs), and field-programmable gate arrays (FPGAs). These solutions help optimise supply chains, lower manufacturing costs, and speed up time to market.

However, selecting the right PLD solution involves trade-offs. CPLDs and FPGAs, for example, support thousands of logic elements and come in various package sizes, often requiring advanced software programming expertise. To address these challenges, Texas Instruments (TI) has introduced a new PLD portfolio that integrates multiple sequential logic and analogue functions into a single package. These devices reduce board space by up to 90% and component count by at least 80% compared to discrete logic implementations.

Configurable Logic, Optimised for Flexibility

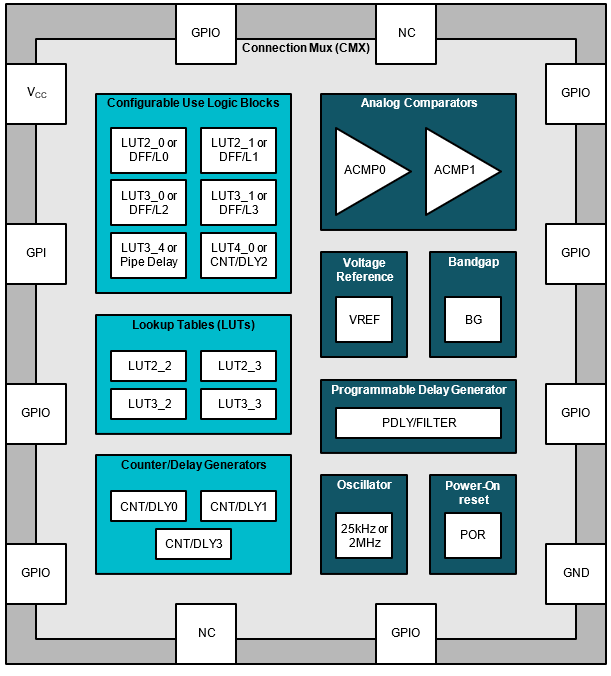

TI’s PLD portfolio includes solutions that integrate key logic functions such as D-type flip-flops, pipe delays, pattern generators, counters, delays, and comparators. Unlike traditional hardware designs that require physical modifications to introduce new functions, TI’s PLDs offer configurable logic elements that adapt to different parameters without additional hardware changes.

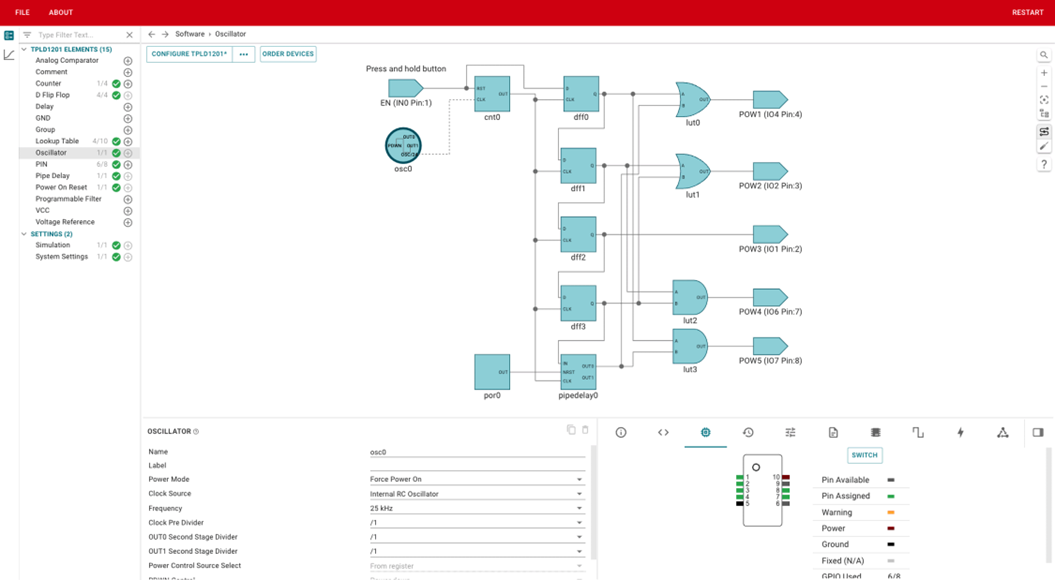

A key advantage is that these devices require zero software development and no hardware description language (HDL) coding, making them accessible for a broad range of engineers. Figure 1 outlines the configurable logic elements of the TPLD1201.

Programmable Logic in Industry-Standard Packaging

Most PLDs on the market are tailored for consumer electronics applications, often requiring specialised packaging. TI’s approach differs by offering PLDs in standard Joint Electron Device Engineering Council (JEDEC) leaded and non-leaded packaging options, ensuring compatibility with automotive and industrial applications.

Key benefits of TI’s PLD portfolio include:

- Standard packaging for seamless integration

- 0.5mm pitch leaded packages for improved solderability

- Automated optical inspection (AOI) compatibility for reliability

- Extended temperature range (-40°C to 125°C) for industrial use

- Automotive Electronics Council (AEC) Q-100 qualification

By maintaining standardised packaging, engineers can implement programmable logic while ensuring compliance with long-term reliability standards in safety-critical applications.

Configure in Seconds – No Coding Required

Configuring a logic device often requires software expertise, but TI PLDs simplify this process with a user-friendly graphical interface. InterConnect Studio, developed with designers in mind, allows engineers to quickly configure logic circuits without any coding experience.

Key features of InterConnect Studio:

- Drag-and-drop interface for intuitive circuit design

- Rapid simulation and evaluation without external programming tools

- One-click configuration via the TPLD programmer and evaluation module

Figure 2 illustrates a power sequencing application designed using InterConnect Studio.

From the menu on the left side of the graphical interface, users can add components with a simple click and drag, connecting them seamlessly within the circuit. Once the simulation is complete, engineers can temporarily configure the device for evaluation or permanently program the PLD by selecting the appropriate option within the tool.

Conclusion

With the increasing need for compact, cost-efficient, and power-optimised solutions, programmable logic devices (PLDs) offer a flexible and scalable approach to logic integration. TI’s PLD portfolio delivers:

- Smaller board designs and lower production costs

- Ultra-low power consumption

- Optimised logic elements with built-in analogue functionality

- No software development or HDL expertise required

By leveraging TI’s programmable logic solutions, engineers now have more options than ever to develop tailored, space-efficient designs that meet their specific application requirements.

Additional Resources

- Explore TI’s growing portfolio of PLDs

- Compare TI PLD products with this parametric table

- Read the application note: Power Sequencing With Feedback Using TI Programmable Logic Devices

- Learn more about Using Lookup-Tables in Programmable Logic