Materials Direct: Your Source for Custom-Cut Materials

17-03-2025 | By Matthew Walker

Key Things to Know:

- Faster, more efficient procurement – Materials Direct eliminates long lead times with rapid order processing and optional 24-hour dispatch.

- No minimum orders or tooling costs – Businesses can order exactly what they need, from single prototypes to high-volume production, without unnecessary fees.

- Automated quoting for instant pricing – An intuitive online system provides real-time pricing and volume discounts, streamlining the ordering process.

- Sustainable and cost-effective – Optimised material use reduces waste, supporting eco-conscious business practices while keeping costs down.

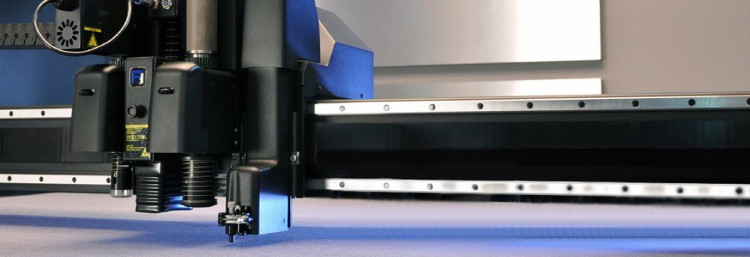

For industries relying on precision-cut materials, the procurement process has often been a slow and inflexible experience. Long lead times, high minimum orders, and unexpected tooling costs have made sourcing thermal interface materials, gaskets, and diffusers more complicated than it needs to be. Materials Direct, a division of Universal Science, is changing that by streamlining the process and removing common barriers that slow businesses down.

Founded in 2002 by James Stratford, a specialist in thermal management and engineering, the company was built on the idea that ordering custom-cut materials should be as straightforward as any other online purchase. By combining advanced manufacturing capabilities with an intuitive digital platform, Materials Direct offers a procurement model that prioritises speed, flexibility, and simplicity—without compromising on quality.

As industries push for faster turnaround times and more efficient supply chains, the need for smarter material sourcing is becoming more critical than ever. Whether it's for aerospace, automotive, industrial applications, or emerging technologies, Materials Direct is reshaping the way businesses access the materials they need.

Fast Turnaround & Global Reach

In industries where project deadlines are tight, waiting weeks for essential materials isn’t an option. Delays in sourcing thermal interface materials, gaskets, or diffusers can slow development cycles, disrupt production schedules, and increase costs. Businesses need a supply chain that keeps up with their pace, not one that holds them back.

Materials Direct addresses this challenge with a procurement model built for speed. Orders are processed quickly, with an optional 24-hour dispatch service ensuring that materials are ready for shipment in as little as a day. This rapid turnaround is particularly valuable in sectors like aerospace, automotive, industrial manufacturing, LED lighting, military, and power, where efficiency and precision are critical.

Global shipping further extends this advantage, eliminating reliance on slow overseas suppliers. Whether a manufacturer needs a one-off rapid prototype or a full production run, Materials Direct ensures materials arrive on time, keeping projects on schedule and reducing the risks associated with supply chain disruptions.

No Minimum Orders, No Tooling Costs – Ultimate Flexibility

For many businesses, sourcing custom-cut materials comes with unnecessary restrictions. Traditional suppliers often impose minimum order quantities (MOQs) and tooling fees, forcing companies to buy more than they need or pay extra just to get started. This lack of flexibility creates inefficiencies, especially for those working on prototypes or low-volume production runs.

Materials Direct removes these constraints, allowing orders of any size—whether it’s a single unit for testing or a high-volume batch for full-scale production. Companies that handle their own converting can also order stock sheets and rolls directly, giving them greater control over their materials.

For businesses managing ongoing production, blanket order scheduling provides even more flexibility. Customers with a credit account can place bulk orders and schedule shipments in batches, ensuring they receive materials exactly when needed without tying up storage space or capital. By eliminating traditional supplier limitations, Materials Direct makes it easier for companies to scale production at their own pace.

Automated Quoting & Expert Support – Simplifying the Process

Material procurement has traditionally been a slow and inefficient process. Long negotiations, back-and-forth communication, and unclear pricing structures can lead to delays that businesses simply can’t afford. Getting a custom-cut part should be straightforward, not a drawn-out exercise in patience.

Materials Direct streamlines this process with an automated online quoting system that delivers instant pricing based on custom specifications. Instead of waiting days for a quote, customers can configure their order, see the cost immediately, and place it within minutes. For larger orders, volume discounts are automatically applied—eliminating the need for manual price negotiations.

Flexibility is built into the system, allowing customers to refine their designs daily without penalties or delays. Whether adjusting dimensions, materials, or quantities, the platform ensures that updates don’t slow down the ordering process. And for businesses that require more than just an instant quote, Materials Direct offers expert technical support to assist with complex orders, material selection, and product optimisation. This combination of automation and expertise makes procurement faster, simpler, and more reliable.

Real-World Use Case: The LED Lighting Company

For businesses working under tight deadlines, even a small delay in material procurement can have significant consequences. A German LED lighting company preparing for a major trade show found itself in exactly this situation. With just days before the event, they needed two custom-cut thermal diffusers to complete their prototype.

Traditional suppliers would have required minimum order quantities, long lead times, or back-and-forth negotiations—none of which were an option. Instead, the company turned to Materials Direct. Using the automated quoting system, they specified their exact requirements, received an instant price, and placed the order within minutes. By selecting the 24-hour dispatch service, they ensured the diffusers were shipped out the next day.

The result? The parts arrived on time, allowing the company to showcase their prototype as planned. The successful presentation led to securing a new client, proving that fast, flexible material sourcing can make a real difference in high-pressure situations.

Sustainability & Waste Reduction – A Greener Supply Chain

Sustainability is no longer just an option—it’s a priority for businesses looking to reduce their environmental impact. From cutting emissions to minimising waste, companies are under increasing pressure to align their supply chains with eco-conscious practices. But traditional material procurement often leads to excess waste, with off-cuts discarded and unused stock sitting in storage.

Materials Direct takes a different approach. By optimising the cutting process, off-cuts from one order are repurposed for future projects, ensuring that nearly nothing goes to waste. This efficient use of materials not only reduces landfill contributions but also helps keep costs down for customers.

Beyond waste reduction, sustainable material sourcing plays a key role. By working with trusted suppliers committed to environmental responsibility, Materials Direct ensures that businesses can meet their procurement needs without compromising their green initiatives. Whether it’s a startup looking to build a more sustainable product line or a large manufacturer meeting corporate social responsibility targets, having a supply chain partner with a built-in commitment to efficiency and sustainability makes all the difference.

A Partner for the Future of Manufacturing

Across industries like aerospace, automotive, industrial manufacturing, LED lighting, military, and power, the demand for high-quality, precision-cut materials is constant. But traditional procurement models—burdened by long lead times, rigid order requirements, and outdated pricing structures—often slow businesses down.

Materials Direct is changing that by combining technical expertise with an innovative, digital-first approach to sourcing custom-cut materials. By streamlining procurement, eliminating unnecessary costs, and offering rapid turnaround times, it provides businesses with the flexibility they need to stay competitive.

As manufacturing continues to evolve, speed and efficiency are more critical than ever. Whether it’s for a one-off prototype or full-scale production, Materials Direct offers a smarter, faster, and more cost-effective way to source materials—helping businesses focus on innovation rather than supply chain challenges.