SeSemi: Bill of Material Management, a Critical Part of Manufacturing…

11-03-2024 | By Jack Pollard

Effective Bill of Materials (BOM) management is fundamental in the manufacturing industry, ensuring the streamlined coordination of supply chains and product lifecycle processes. This article by Aimee Cadle, Managing Director of SeSemi Electronics, highlights the significance of BOM management, emphasising its role in updating and tracking materials and components essential for manufacturing efficiency.

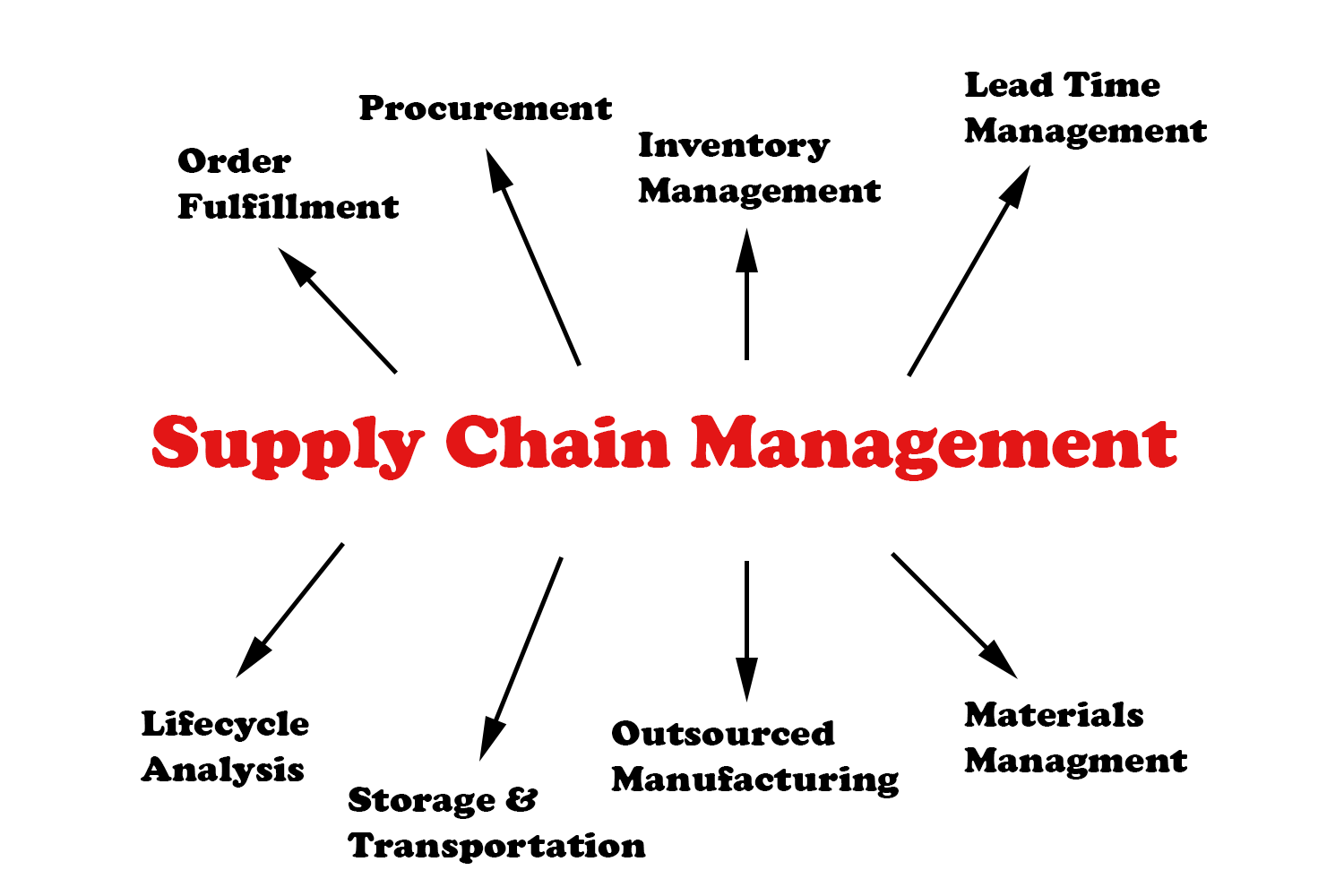

Bill of Material Management is an important aspect of manufacturing. BOMs provides a detailed and structured list of components and materials required to manufacture a product and it is essential they are well managed throughout a product lifecycle. Additionally, BOM management helps optimise the supply chain, managing engineering changes, collaboration across departments and external partners, and supports the overall products life cycle and availability.

Challenges and Solutions of BOM Management

New designs often take a considerable amount of time to reach production stage, often with multiple design changes throughout the sampling process. With technology enhancing so quickly, manufacturers acquiring and merging, and market disruption such as allocation, it’s possible some key components used within the early stages of design may have availability or life cycle changes in that time. Knowing any potential issues prior to putting a final design to market can be critical to avoiding disruption and delays, and that’s where continuous BOM management is important.

Legacy designs are at a greater risk of experiencing issues with obsolescence and are therefore often faced with a continual cycle of product discontinuation. Some industries have requirements for long term life expectancy for products, therefore monitoring your bill of materials will identify changes to a products life cycle as the years go by. Products going end of life or obsolete without appropriate planning in place can create costly delays with manufacturing. Monitoring and planning ensures production will continue with ease.

Impact on Legal Compliance and Customer Expectations

In the electronics industry, products are often subject to various export control regulations and standards. BOM management helps identify such components which is crucial for avoiding legal issues and meeting customers delivery expectations.

In summary, effective BOM management is essential for the smooth and efficient functioning for not just the manufacturing process, but all departments and partners involved.

Are you interested in elevating your manufacturing process with expert Bill of Materials Management? Contact SeSemi direct or visit https://sesemi.co.uk/ to learn more.