Fibre Optic vs Metal Components: Choosing the Right Solution for Your Application

12-02-2025 | By Jack Pollard

This article was written by Mark Baptista, internal application engineer at connector specialist PEI-Genesis.

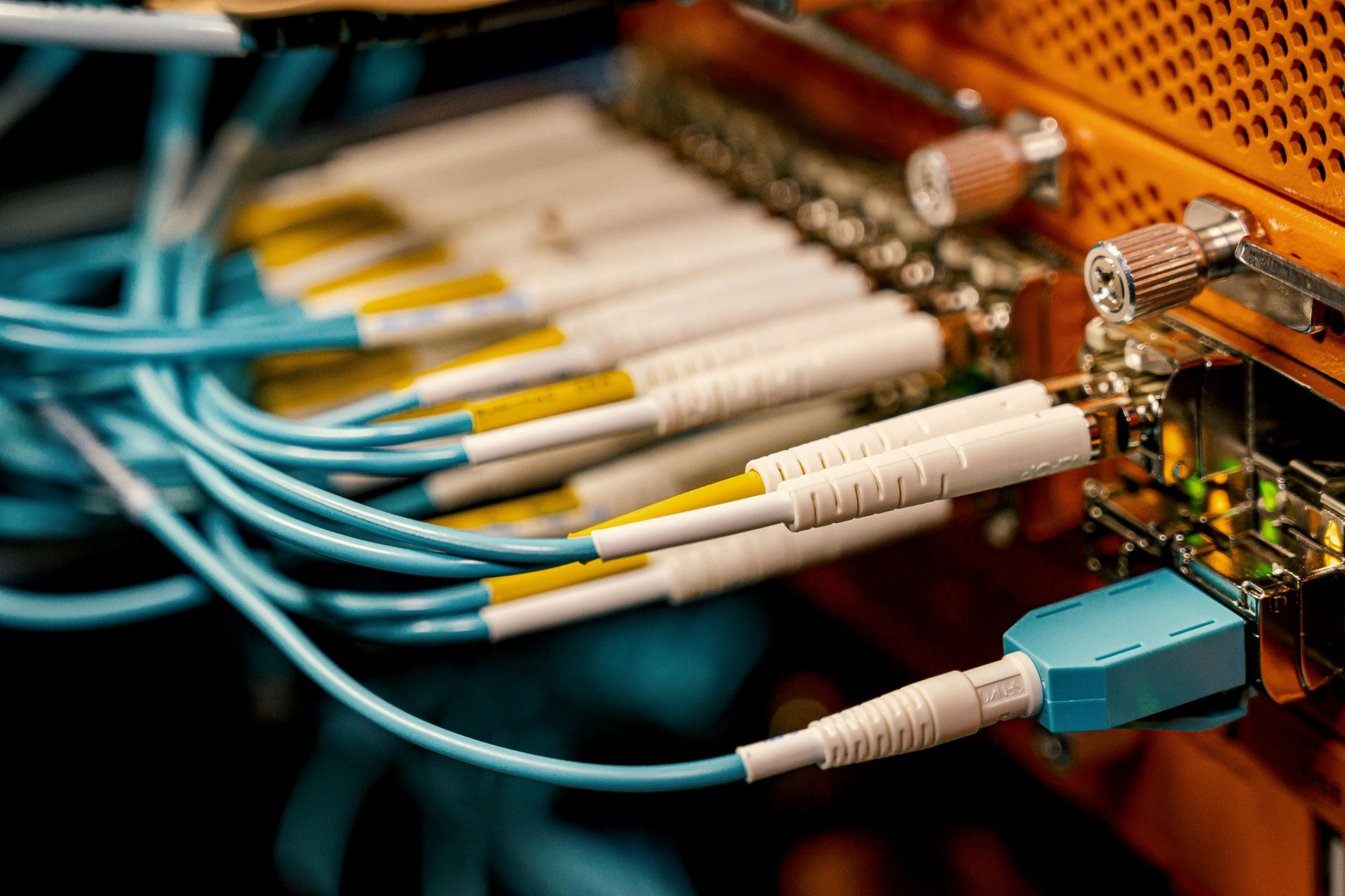

The rise of fibre optic technology has redefined how we transmit data and power, but how does it compare to traditional metal-based cabling? While fibre optics offer high-speed communication and reliability, metal cables remain widely used due to their cost-effectiveness and proven performance. This article by Mark Baptista, Internal Application Engineer at electrical connector specialist PEI-Genesis, explores the advantages and trade-offs between fibre optic and metal-based cables and connectors.

Cost vs Speed: Evaluating Performance and Investment

Traditional metal cabling operates by transmitting electrical signals through conductive materials like copper or aluminium, which offer low resistance and high efficiency. This method has been a staple in industrial, military, and commercial applications due to its affordability and reliability.

On the other hand, fibre optic cables transmit data via pulses of light that travel through glass or plastic fibres. This approach allows for significantly higher bandwidth, making fibre optics ideal for high-speed, data-intensive applications. Fibre optic systems can achieve data transfer rates averaging one gigabyte per second (Gbps), with some high-end applications reaching several terabytes per second (Tbps).

While fibre optics provide a clear advantage in speed, they come at a higher initial cost—typically two to four times more expensive than metal-based alternatives. This upfront investment is offset by fibre’s long-term efficiency and durability, making it a viable choice for applications where speed and reliability are critical.

Durability and Environmental Resistance

Cost is just one factor when choosing between metal and fibre optics—durability plays a crucial role, particularly in challenging environments. Metal cables, while relatively sturdy, are susceptible to electromagnetic interference (EMI) and signal degradation over time. Materials like copper offer corrosion resistance but can be affected by environmental factors, making them less suitable for high-interference environments.

Fibre optic cables, by contrast, are immune to EMI because they rely on light rather than electrical signals. Their non-conductive cores make them ideal for applications in industries such as aerospace, defence, and telecommunications, where consistent, interference-free performance is essential.

Both metal and fibre optic cables can be designed to meet high ingress protection (IP) ratings, ensuring resistance to dust, moisture, and other contaminants. However, fibre optics are often engineered with inherently high IP ratings, whereas metal-based solutions may require additional protective measures to achieve similar durability.

Application-Specific Advantages

The suitability of fibre optics or metal cabling depends largely on the application. Military and aerospace environments, for instance, demand high-speed, interference-resistant solutions. Fibre optic connectors, such as the Fibreco MAXI Expanded Beam Fibre Optic Connector supplied by PEI-Genesis, offer single-mode optical channels for extended transmission distances and multi-mode optical channels for high-speed data transfer over shorter distances. These features make them well-suited for mission-critical communication networks, data centres, and harsh operating conditions.

Fibreco expanded beam connectors exemplify fibre optics’ robustness, operating in temperatures ranging from -40°C to +85°C and withstanding up to 6.7kN of crush resistance. This level of durability ensures reliability even in the most demanding environments.

Conversely, metal cables remain a dependable choice for cost-sensitive, short-term applications where high data rates are not a priority. Their affordability and ease of installation make them suitable for industries where immediate cost savings outweigh the need for high-speed data transfer.

Making the Right Choice

Traditional metal cabling continues to be a reliable and cost-effective option, particularly for applications that do not require extreme data speeds or interference resistance. However, as industries move towards high-speed, secure, and efficient communication networks, fibre optics offer an increasingly attractive alternative, particularly in environments where EMI resistance and long-term durability are paramount.

For engineers and decision-makers, the choice between metal and fibre optics ultimately depends on application-specific needs. Factors such as required data speed, environmental conditions, and budget constraints all play a role in determining the most effective cabling solution.

To explore fibre optic and traditional connector solutions, visit www.peigenesis.com for more insights and product information.

About PEI-Genesis: PEI-Genesis is one of the world’s fastest assemblers of precision connectors and cable assemblies. With the largest connector component inventory in the industry, the company develops tailored solutions for military, industrial, medical, aerospace, transportation, and energy applications. Headquartered in Philadelphia, PA, PEI-Genesis operates production facilities in the US, UK, and China, with global sales offices serving customers across the Americas, Europe, and Asia. Learn more at www.peigenesis.com.